Dear Ray, and LAMMPS users,

Hi,

I’m using LAMMPS to simulate the failure behavior of my ceramic system. To make sure of the validity of structure, potential and etc I first tried to calculate the elastic constants using the codes that is available in Example directory. By doing so, I obtained the correct value for elastic constants. I also checked the lattice constants, and even P.E. of the structure and compared it with the literature and all of the works fine. Up to here everything was calculated in ( P P P ) as bulk material. Then I started a new simulation using ( P P S ) because I want to work on nanomembrane ( Finite thickness in z ). Then I used the below code:

#INITIALIZATION

units metal

boundary p p s

atom_style atomic

#atom_modify map array

#box tilt large

read_data Si3N4.in

pair_style tersoff

pair_coeff * * SiN.Tersoff N Si

------------------------- Minimization ---------------------------------

#replicate 10 6 5

compute stress all stress/atom NULL

compute stress1 all reduce sum c_stress[1]

compute stress2 all reduce sum c_stress[2]

compute stress3 all reduce sum c_stress[3]

compute stress4 all reduce sum c_stress[4]

compute stress5 all reduce sum c_stress[5]

compute stress6 all reduce sum c_stress[6]

thermo 1

thermo_style custom step lx ly lz press pxx pyy pzz pxy pxz pyz pe temp

fix 2 all box/relax x 0 y 0 vmax 0.001

min_style sd

minimize 1.0e-25 1.0e-25 100000 100000

unfix 2

write_data Min.in

------------------------- Equilibration ( NPT ) ---------------------------------

reset_timestep 0

velocity all create 100 277387

fix 1 all npt temp 100 300 0.1 x 0 0 1.0 y 0 0 1.0 drag 0.3

thermo 1000

thermo_style custom step lx ly lz press pxx pyy pzz pxy pxz pyz pe temp

dump q2 all custom 1000 dump.npt.*.cfg id type xs ys zs c_stress[1] c_stress[2] c_stress[3] c_stress[4] c_stress[5] c_stress[6]

#dump_modify q2 element N Si

run 100000

undump q2

unfix 1

write_data EQ2.in

------------------------- Deformation ---------------------------------

reset_timestep 0

variable tmp equal “lx”

variable L0 equal {tmp}

print "Initial Length, L0: {L0}"

fix 1 all npt temp 300 300 0.1 y 0 0 1.0 drag 0.3

fix 2 all deform 1 x erate 0.0001 units box remap x

variable strain equal “(lx - v_L0)/v_L0”

variable p1 equal “v_strain”

variable p2 equal “-pxx/10000”

variable p3 equal “-pyy/10000”

variable p4 equal “-pzz/10000”

variable p5 equal “-pxy/10000”

variable p6 equal “-pxz/10000”

variable p7 equal “-pyz/10000”

thermo 5000

thermo_style custom step v_strain temp v_p1 v_p2 v_p3 v_p4 v_p5 v_p6 v_p7 ke pe press

dump 1 all custom 5000 dump.tensile.*.cfg id type xs ys zs c_stress[1] c_stress[2] c_stress[3] c_stress[4] c_stress[5] c_stress[6]

#dump_modify 1 element N Si

fix def1 all print 500 “{p1} {p2} {p3} {p4} {p5} {p6} ${p7}” file Final.dat screen no

run 150000000

write_data Def.in

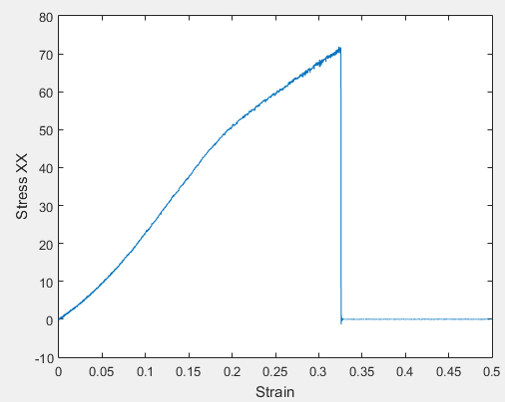

But, the stress strain curve that I obtain is not in good agreement with Literature, especially the stress value at fracture point is too high. As you can see I used -Pxx as the true stress. I wonder if you could please help me out with it.

Thanks,

Ali