Hello,

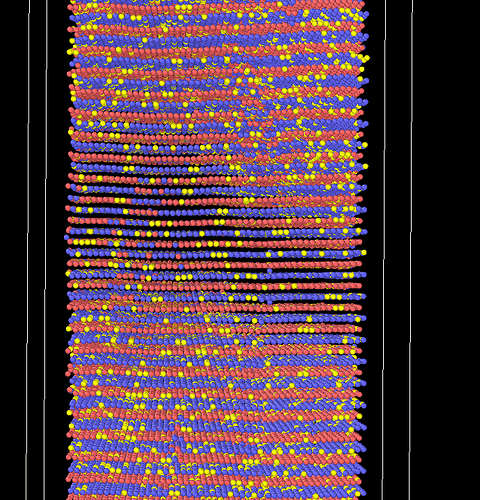

I am using the LAMMPS version 29Oct2020. I have the model of an alloy where there is an equiatomic distribution of Nickel, Chromium and Cobalt (with 50000 atoms), which was created using AtomSK. In my LAMMPS code, I have used the ‘eam/alloy’ potential and initially, I had defined the pair coefficients using the

‘pair_style eam/alloy

pair_coeff * * FeNiCrCoAl-heaweight.setfl Ni Cr Co’ lines, which did not model the interactions between the atoms properly (which I figured out from the final trajectory after tensile loading). I am currently trying out ‘pair_style hybrid’ to define the pair coefficients between each atom type. I am now getting the following error “ERROR: All pair coeffs are not set”. I checked the LAMMPS forums and found a few threads discussing similar errors, but they all had multiple potentials that were being used in their codes. I have only the eam/alloy potential, and I tried modifying my code according to the suggestions in those threads, but nothing worked. Does anyone have any suggestions as to how I can overcome this issue? I am attaching the LAMMPS code along with this. I have the data file and the EAM potentials file that I am using, and if required, I will send it. Thank you!

############ Input file #######################

############ Tensile loading test #######################

############ CoCrNi alloy #######################

############################# INITIALIZATION ###############################

units metal

dimension 3

boundary p p p

atom_style atomic

neighbor 2.0 bin

neigh_modify every 10 delay 0 check yes

############################# ATOM DEFINITION ##############################

read_data CoNi_110.data

############################# FORCEFIELD ###################################

pair_style hybrid eam/alloy eam/alloy eam/alloy

pair_coeff * * eam/alloy 1 FeNiCrCoCu-with-ZBL.eam.alloy Ni Ni NULL

pair_coeff * * eam/alloy 2 FeNiCrCoCu-with-ZBL.eam.alloy Cr Cr NULL

pair_coeff * * eam/alloy 3 FeNiCrCoCu-with-ZBL.eam.alloy Co Co NULL

pair_style hybrid eam/alloy eam/alloy eam/alloy

pair_coeff * * eam/alloy 1 FeNiCrCoCu-with-ZBL.eam.alloy Ni Cr NULL

pair_coeff * * eam/alloy 2 FeNiCrCoCu-with-ZBL.eam.alloy Ni Co NULL

pair_coeff * * eam/alloy 3 FeNiCrCoCu-with-ZBL.eam.alloy Cr Co NULL

############################# GROUP ATOMS ##################################

region 1 block INF INF 141.048 INF INF INF units box

region 2 block INF INF INF 2.0 INF INF units box

group up region 1

group low region 2

group boundary union up low

group mobile subtract all boundary

##---------------SETTINGS-------------------------------------

timestep 0.001

variable ts equal 0.001

Store final cell length for strain calculations

variable tmp equal “lx”

variable Lx equal {tmp}

variable tmp equal "ly"

variable Ly equal {tmp}

variable tmp equal “lz”

variable Lz equal ${tmp}

#print “Initial x Length, Lx: {Lx}"

#print "Initial y Length, Ly: {Ly}”

#print “Initial z Length, Lz: ${Lz}”

##---------------COMPUTES-------------------------------------

#compute 1 all stress/atom NULL

#compute 2 all reduce sum c_1[1] c_1[2]

variable Lx equal lx

variable Ly equal ly

variable Lz equal lz

variable Vol equal vol

variable thickn equal 3.4

print “Initial x Length, Lx: {Lx}"

print "Initial y Length, Ly: {Ly}”

print “Initial z Length, Lz: ${Lz}”

variable strain equal “(lx - v_Lx)/v_Lx”

variable strain1 equal “(ly - v_Ly)/v_Ly”

variable strain2 equal “(lz - v_Lz)/v_Lz”

variable lengthx equal “lx”

variable lengthy equal “ly”

variable lengthz equal “lz”

variable sigmaxx equal “-pxx/10000”

variable sigmayy equal “-pyy/10000”

variable sigmazz equal “-pzz/10000”

variable epsxx equal “v_strain”

variable epsyy equal “v_strain1”

variable epszz equal “v_strain2”

Minimization

min_style cg

timestep 0.001

minimize 1.0e-4 1.0e-6 100 1000

dump 1 all xyz 2000 dump3.xyz

run 10000

Assign original velocities to atoms

compute new all temp

#velocity all create 298.1 487639 temp new

velocity all create 77.0 487639 temp new

run 20000

fix 1 all nvt temp 77.0 77.0 0.1

run 20000

unfix 1

Isobaric-isothermal ensemble

fix 1 all npt temp 77.0 77.0 0.1 iso 0.0 0.0 1000.0

#timestep 0.001

##---------------RELAXATION--------------------------------------

thermo_style custom step temp etotal pxx pyy pzz

thermo_modify flush yes

thermo 1000

dump 3 all xyz 2000 dump3.xyz

run 25000

Fix rigid boundary atoms

compute new2 mobile temp

fix 3 boundary setforce 0.0 0.0 0.0

velocity boundary set 0.0 0.0 NULL

##---------------DEFORMATION--------------------------------------

unfix 1

reset_timestep 0

variable srate equal 5.0e8

#variable srate1 equal “v_srate / 1.0e12”

variable srate1 equal “v_srate / 5.0e10”

fix 5 all deform 1 y erate ${srate1} units box remap x

#run 100

##---------------THERMO-OUTPUTS--------------------------------------

variable CorVol equal f_3[4]*v_thickn/(f_3[3])

variable ConvoFac equal 1/1.0e4

thermo_style custom step temp press etotal v_epsxx v_epsyy v_epszz v_sigmaxx v_sigmayy v_sigmazz pe ke lx ly vol

thermo_modify flush yes

thermo 1000

##---------------OUTPUT--------------------------------------

#fix def1 all print 100 “{epsxx} {epsyy} {epszz} {sigmaxx} {sigmayy} {sigmazz}” file Graphene_100.def1.txt screen no

fix def1 all print 100 “{lengthy} {sigmayy}” file CrCoNiAlloy_110.def1.txt screen no

dump 2 all atom 1000 tensile_test3.lammpstrj

run 270000

Regards,

Rajesh