Dear all,

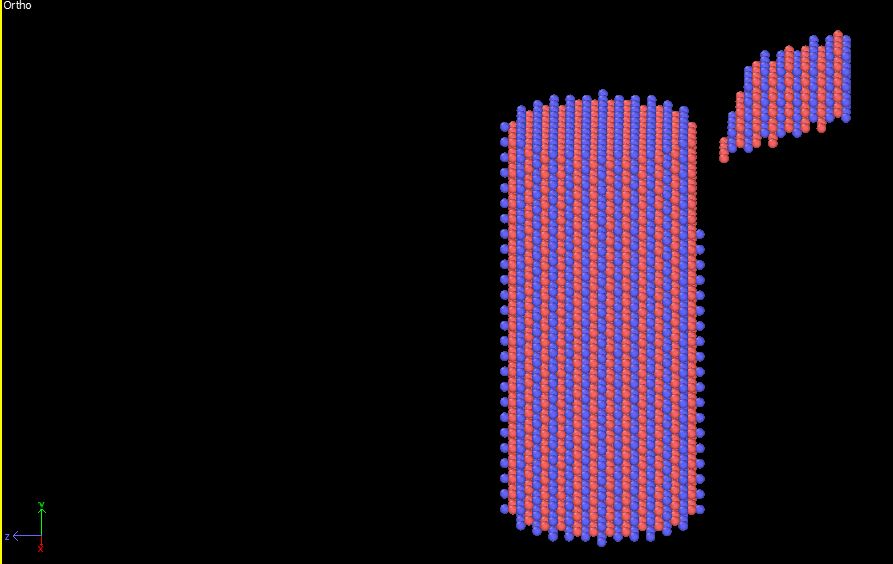

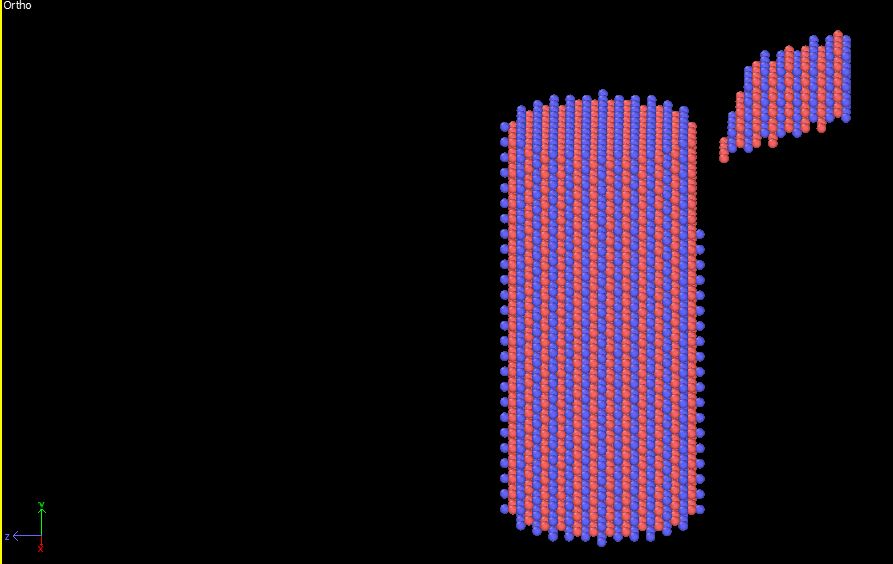

I am currently new in LAMMPS and I am trying to run a nanocutting simulation. What I want to do is to rotate the workpiece about the y-axis and the tool move linearly in the z-axis. Attached you will find an image.

The problem in using the fix move rotate command on the workpiece is that I can’t perform the fix nve time integration on the workpiece (so when the tool moves across the workpiece, no cutting takes place). I can’t do time integration twice on the same atoms.

For that reason, I though it would be useful to use the region move rotate command to rotate the workpiece and then use fix nve to perform time integration on the workpiece. For some reason, when I apply the region move rotate command on the workpiece I get no rotation and I am not sure why. Does anyone know how to solve this issue?

I have attached the script. Any help would be highly appreciated.

Kind Regards,

Fabian

turning2.txt (3.53 KB)

Dear all,

I am currently new in LAMMPS and I am trying to run a nanocutting

simulation. What I want to do is to rotate the workpiece about the y-axis

and the tool move linearly in the z-axis. Attached you will find an image.

and without equilibration? your picture doesn't look like you have

equilibrated the system at all.

The problem in using the fix move rotate command on the workpiece is that

I can't perform the fix nve time integration on the workpiece (so when the

tool moves across the workpiece, no cutting takes place). I can't do time

integration twice on the same atoms.

For that reason, I though it would be useful to use the region move rotate

command to rotate the workpiece and then use fix nve to perform time

integration on the workpiece. For some reason, when I apply the region move

rotate command on the workpiece I get no rotation and I am not sure why.

Does anyone know how to solve this issue?

a moving region does not move the atoms in it, it just matches different

atoms depending on the location of the region.

if you want your cylinder to rotate, yet have the atoms on the surface

react to the cutting tool, you would have to do something more

sophisticated.

the first thing that comes to my mind, is to split the cylinder (workpiece)

into two regions: a core and the rest including the surface. now define two

groups based on those regions, and then apply fix move to the core atoms

and fix nve to the others.

axel

another option would be to use fix addtorque and fix nve. this would be equivalent to using fix addforce and fix nve to induce a translational movement.

the core difference is that with adding a torque (or force), the system will gradually accelerate unless there is something that dissipates the energy added by the added torque/force, while with fix move and prescribed motion will be executed.

axel.

Thank you for the last reply.

I have attempted to split the cylinder into different regions, with a core and an external region. I am applying fix move to the core region and fix nve on the external region but I all I get is the core region rotating and the exernal region stays static. It seems as if the regions don’t act as one body. Do you know what might be causing the issue? I appreciate your help!

Attached you will find the script that I am using.

Many thanks,

Fabian

turning2.txt (3.57 KB)

fabian,

in.rotatebycore (1.26 KB)

Hi Axel,

Thank you very much for your help! I really appreciate your time. I have just tried it with Cu-Zr alloy and it is giving very good results. It has also helped me understand how MD works a lot better so I appreciate it!

All the best,

Fabian