Dear All,

I am doing uni-axial tension on glassy polymers with period boundary conditions along 3 dimensions.

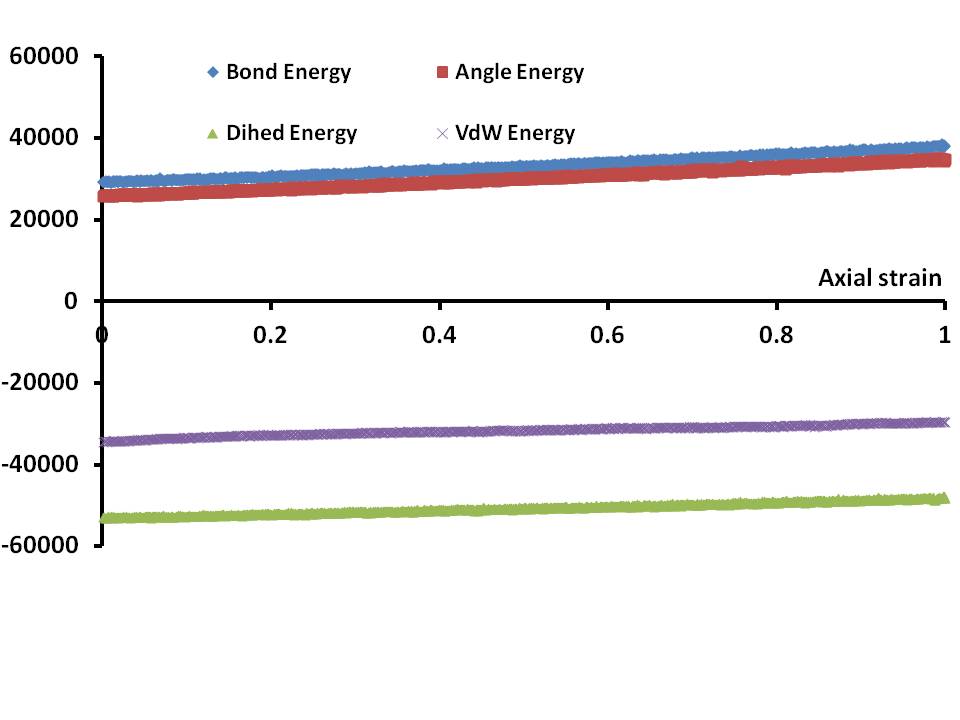

But the Bond/Angle/Torsion/VdW energies DO NOT change as the strain increases, they are just constant during deformations. We use PCFF potential.

As a reference, in “A general inelastic internal state variable model for amorphous glassy polymers” by Bouvard et al, they have the Bond/Angle/Torsion/VdW energies changing as the strain increases. They use DREIDING potential.

Can anyone please help me figure out where this problem from? My input file is below.

Thanks a lot.

Lili Zhang

units real

boundary p p p

atom_style full

pair_style lj/class2 10.0

bond_style class2

angle_style class2

dihedral_style class2

improper_style class2

read_restart restart.ACBPA6030

variable strain equal “ln(1 + (lx - v_L0)/v_L0)”

variable p1 equal “v_strain”

variable p2 equal “-pxx*.101325”

variable p3 equal “-pyy*.101325”

variable p4 equal “-pzz*.101325”

variable p5 equal “pe”

variable p6 equal “7.603e5/vol”

variable p7 equal “(press-pxx-pyy)*.101325”

variable e1 equal “ebond”

variable e2 equal “eangle”

variable e3 equal “edihed”

variable e4 equal “evdwl”

variable tmp equal “lx”

variable L0 equal ${tmp}

print “Initial Length, L0: ${L0}”

timestep 1

fix 1 all nph y 1 1 1000 z 1 1 1000

fix 2 all deform 1 x trate 1e-6 units box remap x

Output strain and stress info to file

for units real, pressure is in [atmospheres]

fix def1 all print 1000 “{p1} {p2} {p3} {p4} {p5} {p6} {e1} {e2} {e3} {e4}” file ACBPA6030.txt screen no

Use cfg for AtomEye

dump 1 all cfg 10000 ACBPA6030_*.cfg id type xs ys zs fx fy fz mol

Display thermo

thermo 100

thermo_style custom step v_strain temp v_p2 v_p3 v_p4 ke pe press v_p6 v_e1 v_e2 v_e3 v_e4 v_p7

run 1000000