Thank you for your reply.

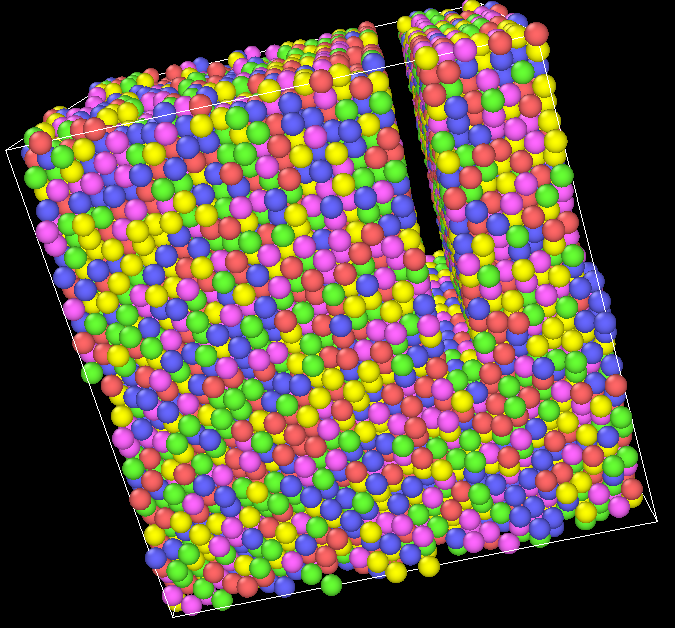

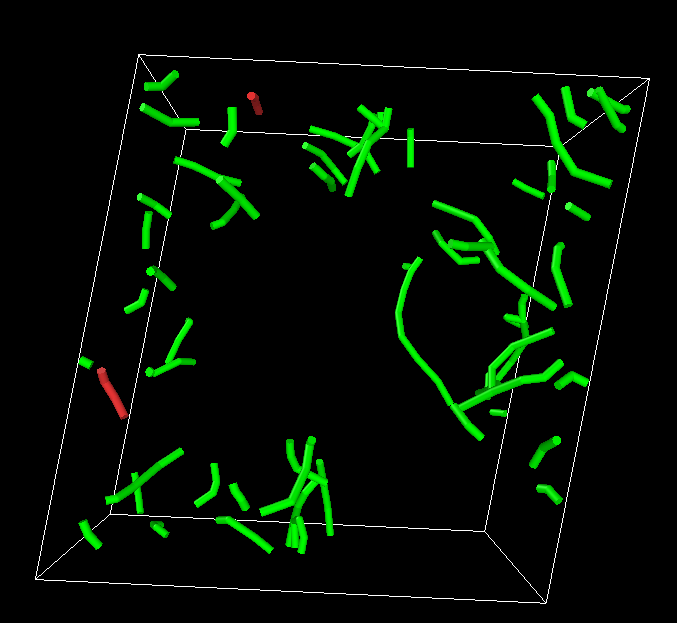

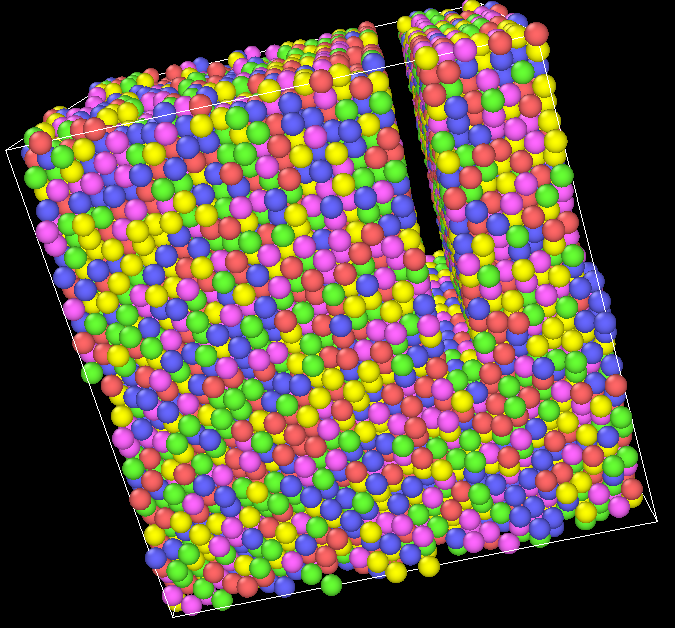

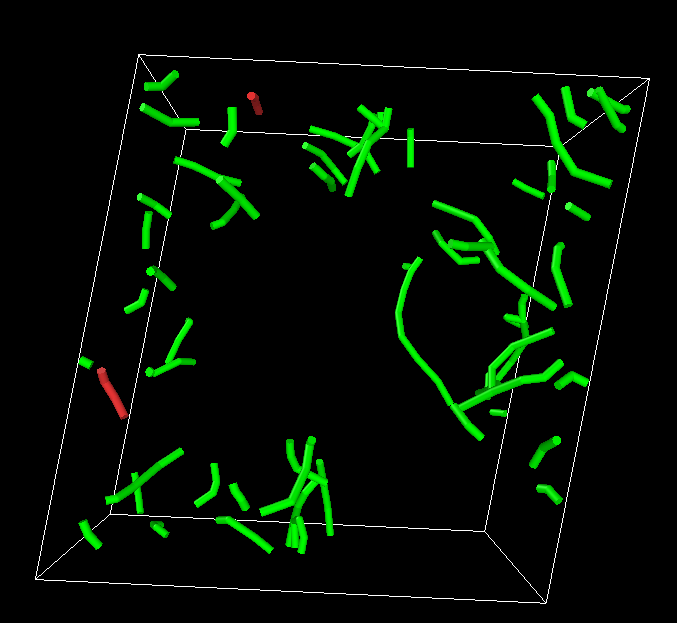

I tried to achieve the same (hard particle in an alloy matrix) by using in.shear example from lammps examples and it is able to generate dislocations well. I wanted to calculate the shear stress at the same time so I am using compute stress atoms to get the stress in the mobile region. I have marked it in bold in my code below.

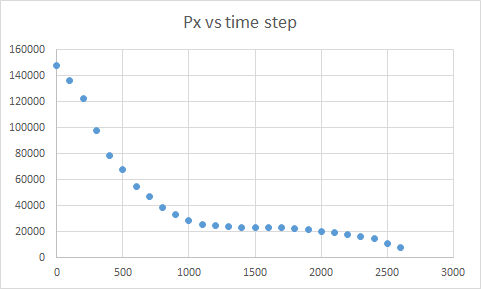

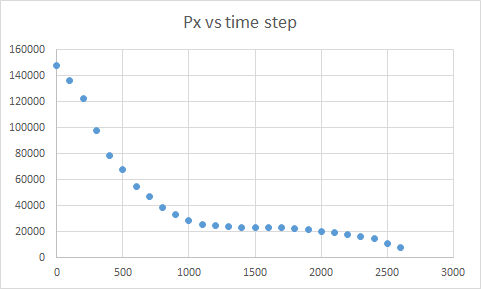

The problem is that I see a decreasing shear stress. I would expect an increasing trend since we are shearing the box and the stress should rise with strain.

Could you kindly tell me where I am going wrong?

Also what would be an ideal approach to calculate the shear strain in this example?

units metal

boundary s s p

atom_style atomic

lattice fcc 3.52

region box block 0 16.0 0 10.0 0 8 #2.828427

create_box 7 box

lattice fcc 3.52 orient x 1 0 0 orient y 0 1 1 orient z 0 -1 1 &

origin 0.5 0 0

create_atoms 1 box

variable fa equal 50000

variable fb equal 37609

variable fc equal 24933

variable fd equal 12421

variable fe equal 10

variable ff equal 1

variable ft equal 62500

set type 1 type/fraction 2 (v_fa/v_ft) 1734536

set type 2 type/fraction 3 (v_fb/(50000)) 1734535

set type 3 type/fraction 4 (v_fc/(37609)) 1734534

set type 4 type/fraction 5 (v_fd/(24933)) 1734533

set type 5 type/fraction 6 (v_fe/(12421)) 1734533

set type 6 type/fraction 7 (v_fe/(12457)) 1734533

group Co type 1

group Cu type 2

group Cr type 3

group Fe type 4

group Ni type 5

group W type 6

group Al type 7

pair_style eam/alloy

pair_coeff * * CoCuCrFeNiWAl.set Co Cu Cr Fe Ni W Al

neighbor 0.3 bin

neigh_modify delay 5

region lower block INF INF INF 0.9 INF INF

region upper block INF INF 6.1 INF INF INF

group lower region lower

group upper region upper

group boundary union lower upper

group mobile subtract all boundary

set group lower type 2

set group upper type 3

void

region void1 sphere 8 3.5 3 2 side in

create_atoms 1 region void1

group void1 region void1

set group void1 type 7

region void2 sphere 8 3.5 3 1 side in

#lattice bcc 3.17 orient x 1 0 0 orient y 0 1 0 orient z 0 0 1

create_atoms 1 region void2

group void2 region void2

set group void2 type 6

fix 111 void2 rigid single

neighbor 2.0 bin

neigh_modify delay 10 check yes