I am simulating a graphene sheet sandwiched between Al alloy particles using the following code.

dimension 3

units metal

boundary p p p

atom_style atomic

atom_modify map array

comm_modify cutoff 5.25

variable sixth equal “1/6”

variable twothirds equal “2/3”

variable alattice equal “2.4595”

variable a1lattice equal “1”

variable a2lattice equal “1.73203”

lattice custom {alattice} a1 {a1lattice} 0 0 a2 0 {a2lattice} 0 basis 0 0 0 basis 0.5 {sixth} 0 basis 0.5 0.5 0 basis 0 ${twothirds} 0

variable boxside equal 200

variable xside equal “round(v_boxside/v_a1lattice/v_alattice/2)” #round ensures that we get complete unit cells

variable yside equal “round(v_boxside/v_a2lattice/v_alattice/2)”

region box block -{xside} {xside} -{yside} {yside} -3 3 units lattice

region graphene block -{xside} {xside} -{yside} {yside} 0 0.1 units lattice

create_box 4 box

create_atoms 4 region graphene

mass * 12.011

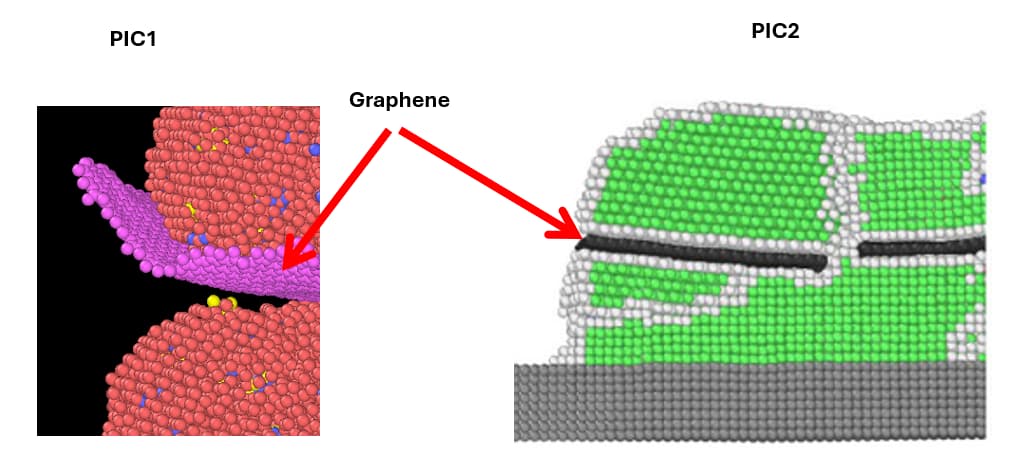

The issue is that when I increase the temperature of the system, the graphene sheets curl up, as shown in pic1. I expected them to look like in pic2 after the alloy melts.

Any suggestion is highly appreciated.