Hi !

I am a first-year graduate student, recently began to use LAMMPS application in EDM analysis, the specific effect I want to do and my code is as follows, please help me to see what the problem is.

Initialization

units metal

dimension 3

boundary p p p

atom_style atomic

#Define the simulation area

region whole block 0 300 0 300 0 500 units box

create_box 2 whole

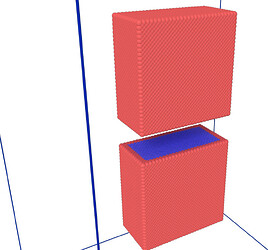

Create an electrode

lattice fcc 3.615

region electrode block 100 200 100 150 230 330 units box

create_atoms 1 region electrode

group electrode region electrode

Create artifacts

lattice fcc 3.615

region workpiece block 100 200 100 150 100 200 units box

create_atoms 2 region workpiece

group workpiece region workpiece

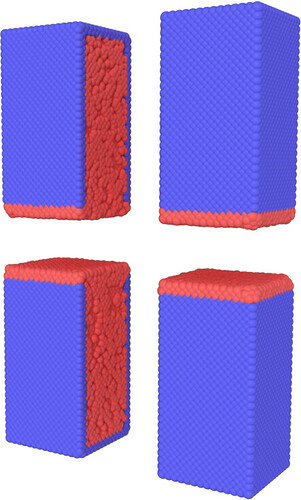

Define the side boundary layer area of the electrode

region el_side2 block 195 200 100 150 230 325 units box

region el_side3 block 105 195 100 105 230 325 units box

region el_side4 block 105 195 145 150 230 325 units box

region el_side5 block 100 200 100 150 325 330 units box

region wp_side1 block 100 105 100 150 100 200 units box

region wp_side2 block 195 200 100 150 100 200 units box

region wp_side3 block 105 195 100 105 100 200 units box

region wp_side4 block 105 195 145 150 100 200 units box

group el_side2 region el_side2

group el_side3 region el_side3

group el_side4 region el_side4

group el_side5 region el_side5

group wp_side1 region wp_side1

group wp_side2 region wp_side2

group wp_side3 region wp_side3

group wp_side4 region wp_side4

The thermostatic region of the electrode

region el_hwc block 105 195 105 145 305 325 units box

region wp_hwc block 105 195 105 145 100 120 units box

region hwc union 2 el_hwc wp_hwc

group el_hwc region el_hwc

group wp_hwc region wp_hwc

group hwc region hwc

Newtonian layer

region el_ndc block 105 195 105 145 230 305 units box

region wp_ndc block 105 195 105 145 180 200 units box

region ndc union 2 el_ndc wp_ndc

group wp_ndc region wp_ndc

group el_ndc region el_ndc

group ndc region ndc

Define atomic type and mass

mass 1 63.546 # Cu

mass 2 63.546 # Cu

Select the applicable force field

pair_style eam/alloy

pair_coeff * * Cu_Zhou04.eam.alloy Cu Cu

Fixed the motion of atoms in the boundary layer on four sides

fix fix_el_side2 el_side2 setforce 0.0 0.0 0.0

fix fix_el_side4 el_side4 setforce 0.0 0.0 0.0

fix fix_el_side5 el_side5 setforce 0.0 0.0 0.0

fix fix_wp_side1 wp_side1 setforce 0.0 0.0 0.0

fix fix_wp_side2 wp_side2 setforce 0.0 0.0 0.0

fix fix_wp_side4 wp_side4 setforce 0.0 0.0 0.0

#Set the initial temperature

velocity all create 300 12345

Application of constant temperature layer

fix nvt_hwc hwc nvt temp 300 300 0.1

Workpiece temperature

fix 2 wp_ndc nvt temp 300 300 0.1

Apply temperature control to the electrode

fix 3 el_ndc nvt temp 300 300 0.1

A variable that controls whether the heat source is activated or not, stop heating after 15000 steps

variable heat_active equal “step < 15000”

variable heat_mult equal “v_heat_active * 20.8”

variable heat_mult_2 equal “v_heat_active * 8.8”

The first heat source

variable x0 equal 120

variable y0 equal 115

variable z0 equal 240 # Central position of heat source

variable Pm equal ${heat_mult} # Maximum heating intensity

variable k equal 0.03 # Parameters that control the range of Gaussian distribution

variable fx atom v_Pmexp(-v_k((x-v_x0)^2+(y-v_y0)^2+(z-v_z0)^2))

variable fy atom v_Pmexp(-v_k((x-v_x0)^2+(y-v_y0)^2+(z-v_z0)^2))

variable fz atom v_Pmexp(-v_k((x-v_x0)^2+(y-v_y0)^2+(z-v_z0)^2))

Applying the force of Gaussian distribution to the Newtonian layer

fix heat el_ndc addforce v_fx v_fy v_fz

The second heat source

variable x0_2 equal 155

variable y0_2 equal 130

variable z0_2 equal 210

variable Pm2 equal ${heat_mult_2}

variable k equal 0.03

variable fx_2 atom v_Pm2exp(-v_k((x-v_x0_2)^2+(y-v_y0_2)^2+(z-v_z0_2)^2))

variable fy_2 atom v_Pm2exp(-v_k((x-v_x0_2)^2+(y-v_y0_2)^2+(z-v_z0_2)^2))

variable fz_2 atom v_Pm2exp(-v_k((x-v_x0_2)^2+(y-v_y0_2)^2+(z-v_z0_2)^2))

fix heat2 wp_ndc addforce v_fx_2 v_fy_2 v_fz_2

thermo 500

thermo_style custom step temp pe ke etotal press pxx pyy pzz

dump 1 all custom 500 dump.Cu.xyz id type x y z

run 60000

I follow the production of this article, I feel that there is something wrong with my Gaussian heat source setting, because this article does not specify how to set it.(Influence of discharge gap on material removal and melt pool movement in EDM discharge process (https://doi.org/10.1007/s00170-021-08577-z))

I think the key lies in the setting of the heat source. I am not sure how to set the heat source properly to achieve the effect in the article. Of course, my other settings are also rough. Please give suggestions.