Hello everyone,

I am trying to validate a paper on AlSi10Mg alloy:

“Effect of fabrication process parameters and graphene reinforcement on mechanical behaviour of additively manufactured AlSi10Mg alloy – A molecular dynamics simulation study.”

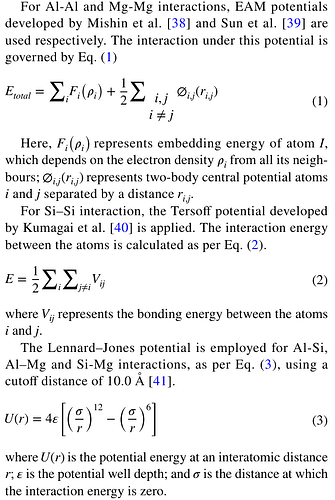

I am facing issues creating the correct hybrid potential for the alloy as described in the paper.

What I did so far:

- Built the atomic structure using Python, LAMMPS, and MATLAB

- After running the simulation, the atoms spread apart instead of forming a stable structure

- I suspect the issue is with my Lennard-Jones (LJ) parameters

- I cannot find suitable ε (epsilon) and σ (sigma) values for the cross-interactions:

Al–Si

Si–Mg

Al–Mg

Below is the input script I used (simplified):

LAMMPS input script for AlSi10Mg (incomplete example)

‘’’ units metal #gm/mole, angstrom, ps, ev, bars, K, gm/cc

dimension 3

boundary p p m

atom_style atomic

simulation box and lattice,potential files

lattice fcc 1.0

region whole block 0 60 0 60 0 60 units box

create_box 3 whole

read_data alsimg_sphere.data add append

-------------------- POTENTIAL SETUP --------------------

Atom type mapping:

1 = Al

2 = Si

3 = Mg

Hybrid/overlay: allows EAM, Tersoff, AIREBO, and LJ cross terms

pair_style hybrid/overlay eam/alloy eam/fs tersoff lj/cut 10.0

pair_coeff * * eam/alloy Al99.eam.alloy.txt Al NULL NULL

pair_coeff * * tersoff Si.tersoff NULL Si NULL

pair_coeff * * eam/fs Mg.eam.fs.txt NULL NULL Mg

Cross-interactions using Lennard-Jones

pair_coeff 1 2 lj/cut 0.01954 3.91728 # Al–Si

pair_coeff 1 3 lj/cut 0.01026 3.34978 # Al–Mg

pair_coeff 2 3 lj/cut 0.00915 3.25891 # Si–Mg

reset_timestep 0

timestep 0.0001

fix NVE all nve

thermo 100

dump mydump all custom 100 mydump*.txt id type x y z vx vy vz

run 1000

write_data mydata.data

quit ‘’’

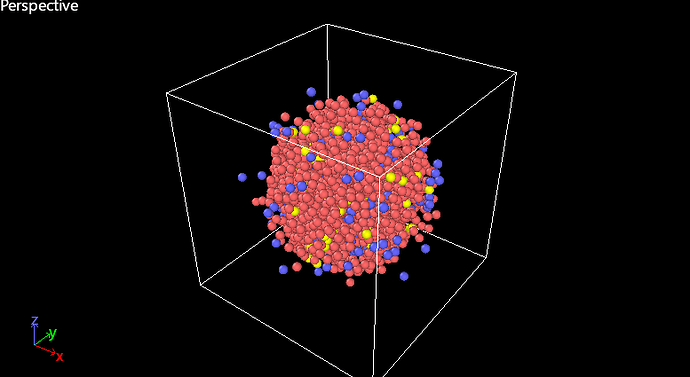

After running, the structure looks like this (screenshot attached).

My questions:

Does anyone know reliable LJ (or alternative) potential parameters for AlSi10Mg?

Am I correct to assume that the spreading issue is due to incorrect LJ parameters?

Would another potential type (e.g., EAM + LJ hybrid) be more suitable for this alloy system?

Any guidance would be highly appreciated!

Thank you,

Tasmiah Zaman