Good day to everyone!

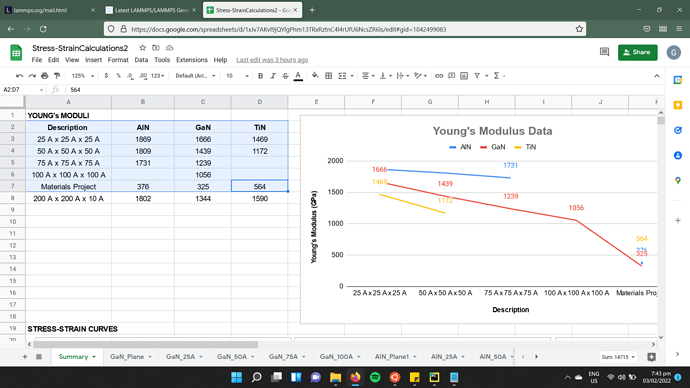

I’ve run multiple simulations where I stretch cubic models of AlN, GaN, and TiN along their x-axis at a constant strain rate. The initial runs yielded Young’s modulus values (taken as the slope of the generated stress-strain curves) that were way beyond experimental and theoretical values recorded in literature. As advised by my mentors, I ran further simulations that varied the size of the initial models to see if larger sizes would bring my results closer to known values. While it did, the results were still quite high (see screenshot attached).

Given all that, I wonder if there are ways to improve my results aside from increasing the model size (something that my laptop is poorly equipped to handle.) I’m considering varying the strain rate and initial system temperature after equilibration.

My input scripts generally follow this flow (following this LAMMPS tutorial: Uniaxial Tension - EVOCD):

------------------------ INITIALIZATION ----------------------------

units metal

atom_style atomic

dimension 3

boundary p p p

atom_modify map array

------------------------- SETTINGS ---------------------------------

variable a equal 3.00770274

variable b equal 3.00770274

variable c equal 3.00770274

#lattice hcp ${latconst}

region whole block 0 $a 0 $b 0 $c units lattice

create_box 2 whole

#create Ti atoms

lattice custom 1.0 &

a1 $a 0.0 0.0 &

a2 0.0 $b 0.0 &

a3 0.0 0.0 $c &

basis 0.50000000 0.50000000 0.50000000

create_atoms 1 region whole

#create N atoms

lattice custom 1.0 &

a1 $a 0.0 0.0 &

a2 0.0 $b 0.0 &

a3 0.0 0.0 $c &

basis 0.00000000 0.00000000 0.00000000

create_atoms 2 region whole

replicate 8 8 8

------------------------- POTENTIAL ---------------------------------

pair_style meam/c

pair_coeff * * libraryTiN.meam Ti N TiN.meam Ti N

neighbor 2.0 bin

neigh_modify delay 10 check yes

#-------------------------- COMPUTATIONS -------------------------------

compute csym all centro/atom fcc

compute peratom all pe/atom

------------------------- EQUILIBRATION ------------------------------------

reset_timestep 0

timestep 0.001

velocity all create 300 12345 mom yes rot no

fix 1 all npt temp 300 300 1 iso 0 0 1 drag 1

Set thermo output

thermo 10

thermo_style custom step lx ly lz press pxx pyy pzz pe temp

dump 1 all custom 10 equilibration_TiN.lammpstrj id type x y z ix iy iz c_peratom c_csym

write_data data.relaxationTiN

run 50000

unfix 1

undump 1

Store final cell length for strain calculations

variable tmp equal “lx”

variable L0 equal {tmp}

print "Initial Length, L0: {L0}"

------------------------- DEFORMATION ------------------------------------

reset_timestep 0

write_restart restart.TiN

fix 1 all npt temp 300 300 1 y 0 0 1 z 0 0 1 drag 1

variable srate equal 1.0e10

variable srate1 equal “v_srate / 1.0e12”

fix 2 all deform 1 x erate ${srate1} units box remap x

variable strain equal “(lx - v_L0)/v_L0”

variable p1 equal “v_strain”

variable p2 equal “-pxx/1000”

variable p3 equal “-pyy/1000”

variable p4 equal “-pzz/1000”

fix def1 all print 100 “{p1} {p2} {p3} {p4}” file TiN.deformation.txt screen no

thermo 10

thermo_style custom step v_strain temp v_p2 v_p3 v_p4 ke pe press

dump 1 all custom 10 deformation_TiN.lammpstrj id type x y z ix iy iz c_peratom c_csym

write_data data.deformationTiN

dump 2 all custom 10 data.atoms_deformation_TiN id type x y z ix iy iz

run 300000

Thank you very much for your time and patience!