Dear lammps developers.

I am using lammps to make particle discrete elements and the purpose I want to achieve is the agglomeration of granular powders and the breaking up of agglomerates using ultrasonic waves.

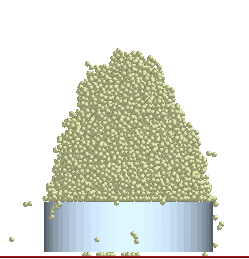

In lammps I placed a cylinder at the bottom and the particles fell from above, but I found that the particles did not pile up on the cylinder as expected, but went straight through it.

(particle-particle and particle-wall contact modell are both jkr modell)

Following your last reply I have reduced the gravity and reduced the velocity of the particles and adjusted the time step to the minimum Rayleigh time step.

For lammps I think I must have missed some important steps and still haven’t found a relevant solution. If you have time,could you give me some valuable advice

sincerely,

cute

code is attached below

variable name string pour_into_box

atom_style sphere

units si

###############################################

Geometry-related parameters

###############################################

variable boxx equal 1000e-6

variable boxy equal 1000e-6

variable boxz equal 1300e-6

###############################################

Particle-related parameters

###############################################

variable rlo equal 7e-6

variable rhi equal 9e-6

variable dlo equal 2.0*{rlo}

variable dhi equal 2.0*{rhi}

variable dens equal 944.3038

variable skin equal 0.3*${rhi}

region boxreg block 0 {boxx} 0 {boxy} 0 ${boxz}

create_box 1 boxreg

change_box all boundary p p f

################################

#particle contact modell

################################

pair_style granular

pair_coeff 1 1 jkr 2.5e7 0.35 0.25 0.003 tangential mindlin 8e6 1.0 0.695 rolling sds 200 100 0.13 twisting marshall

comm_modify vel yes

region insreg1 cylinder z 500e-6 500e-6 100e-6 400e-6 900e-6

region cyl cylinder z 500e-6 500e-6 250e-6 0 50e-6 side out

fix 1 all nve/sphere

fix grav all gravity 1.0 vector 0 0 -1

fix ins1 all pour 8000 1 2555 region insreg1 vel 0 0 0 0 -0.0001 diam range {dlo} {dhi} dens {dens} {dens}

neighbor ${skin} bin

neigh_modify delay 0 every 1 check yes

#################################

#particle- wall contact modell

#################################

fix 2 all wall/gran/region granular jkr 1.8e11 0.35 0.3 0.0395 tangential mindlin 2000 1.0 0.6 rolling sds 500.0 200.0 0.405 twisting marshall region cyl

thermo_style custom step atoms ke

thermo_modify lost warn

thermo 100

compute 1 all ke

compute 2 all erotate/sphere

timestep 5.82e-8

dump 1 all custom 100 ${name}.dump id type radius mass x y z

run 3000000