Hi!

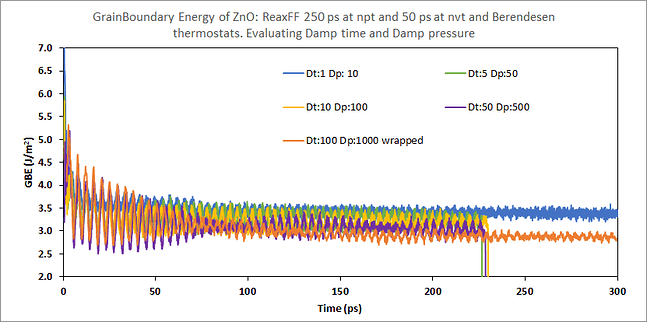

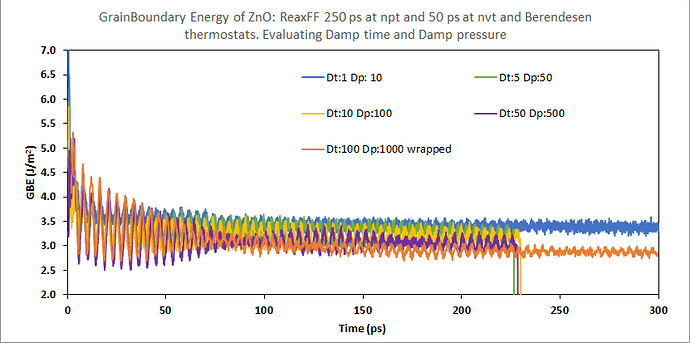

I’m running two consecutive equilibrations on LAMMPS, the first at NPT (250 ps) and the second at NVT + Berendsen (50 ps) to calculate the grain boundary energy of ZnO.

The structure presents some periodic oscillations that we would like to avoid, or at least for it to be minimum. If possible just getting noise at the end (similar to the blue plot at the last 50 ps).

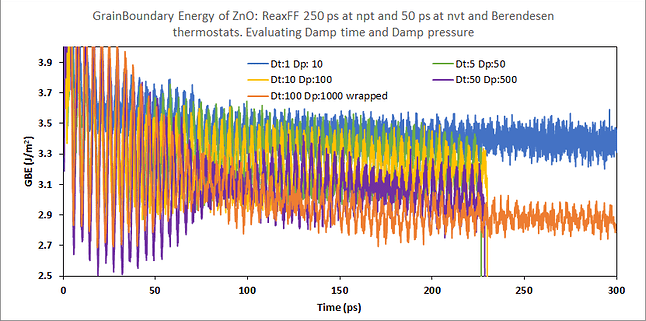

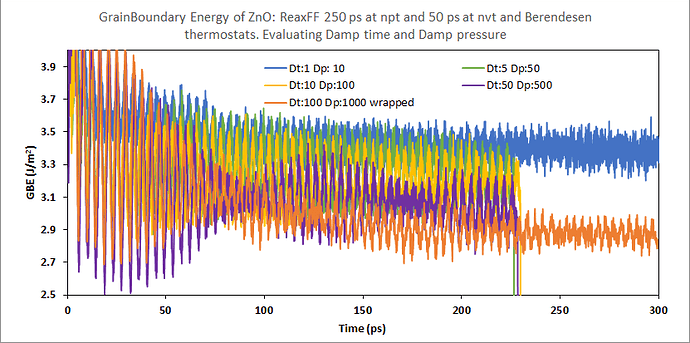

Just zooming in:

Initially, we were using Damp time of 100 fs and Damp pressure of 1000 fs (orange plot), oscillations persisted until the end. When we shifted to Dt: 1 fs and Dp: 10 fs to amplitude was still significant, but the pattern was of noise, however there was a significant offset (increase) of the final value. I’m currently testing some intermediary Dt and Dp combinations, always Dp = 10 Dt.

Do you have suggestions on what to adjust to avoid oscillations while getting a meaningful (not forced) value of the grain boundary energy?

Previous

----------- Equilibration 1 ---------------------------

reset_timestep 0

timestep 0.25

fix 3 all npt temp 300.0 300.0 100.0 aniso 1.0 1.0 1000.0

thermo 500

run 1000000

unfix 3

----------- Equilibration 2 ---------------------------

reset_timestep 0

timestep 0.25

fix 6 all nvt temp 300.0 300.0 100.0

fix 7 all temp/berendsen 300.0 300.0 100.0

thermo 500

run 200000

New

----------- Equilibration 1 ---------------------------

reset_timestep 0

timestep 0.25

fix 3 all npt temp 300.0 300.0 1 aniso 1.0 1.0 10

thermo 100

run 1000000

unfix 3

----------- Equilibration 2 ---------------------------

reset_timestep 0

timestep 0.25

fix 6 all nvt temp 300.0 300.0 1

fix 7 all temp/berendsen 300.0 300.0 1

thermo 100

run 200000

Thank you in advance!

Best,

Gustavo