Hi lammps users,

I am trying to simulate a tension test on polymer nanocomposite. I could successfully do it with periodic b.c in all directions (p p p). But I observed that carbon nanotube bonds were broken before that of polymers. But in real testing, polymers should fail before CNT. I believe this was because of periodicity in the tension direction (please correct me if I am wrong here) since polymers can move around in the box and do not get the effect of tension. So I tried with p p s boundary condition, setting boundary atom force to zero, apply a velocity to the top group of atoms and integrating with nve. I observed that the top atoms moved apart and broke out, all other atoms did not experience any tension effect. Also, temp shoots up because of this movement of atoms. Does anyone have any suggestions on this?

Regards

Abhiram

i disagree with your reasoning. whether bonds break is due how strong they are and that is determined by the force field, not periodic boundaries.

Thanks, axel for your reply. I am simulating CNT polyethylene nanocomposite with Reaxff. Reaxff should be able to capture the bond-breaking phenomenon as far as my knowledge. Here when I tried tension with p p p b.c, CNT bonds broke. But CNT is much stronger than polyethylene when subjected to tension. Also, I tried tension on just polyethylene with the same approach, I could see polymers moving around, but no bonds being broken. Please check the attached code on polyethylene simulation. I haven’t attached the bond output and dump file from the reax/c code because of its file size. Do you have any suggestions why polyethylene bonds do not break here?

control_file (690 Bytes)

ffield.reax.cho (7.97 KB)

param.qeq (49 Bytes)

log.lammps (32 KB)

input.pe_restart (1.17 KB)

Sorry, I attached the same file twice. Here is a file I missed

Please look at this comment in the reaxff force field file:

Reactive MD-force field c/h/o combustion force field

This is completely unsuitable for studying your system. ReaxFF force field parameters are very specific to the environment and systems they are parameterized for.

Hi Axel,

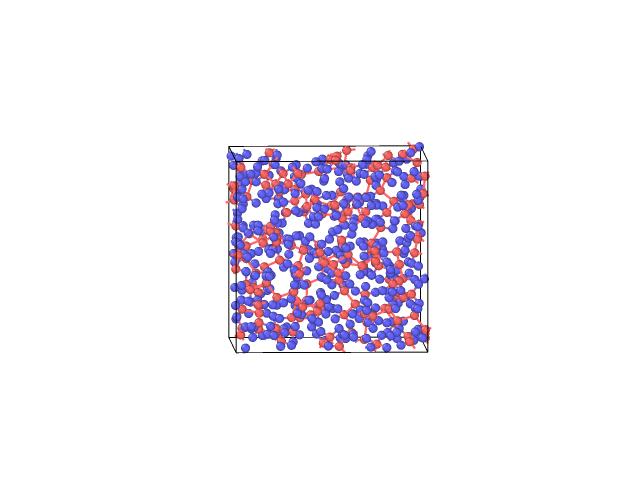

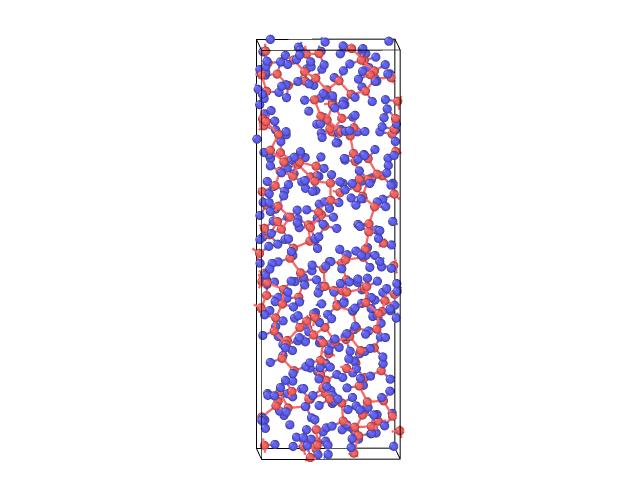

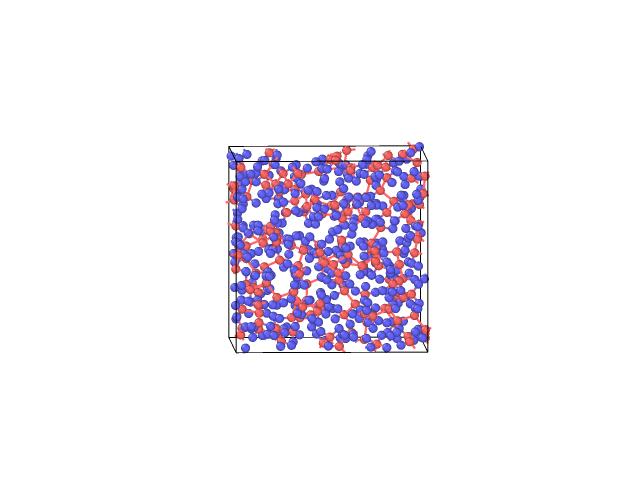

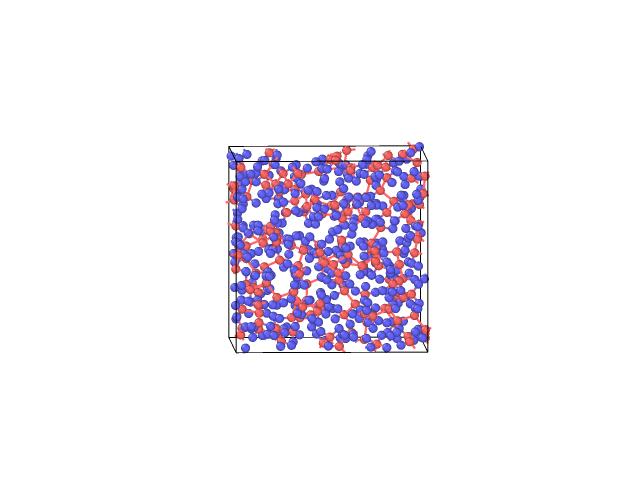

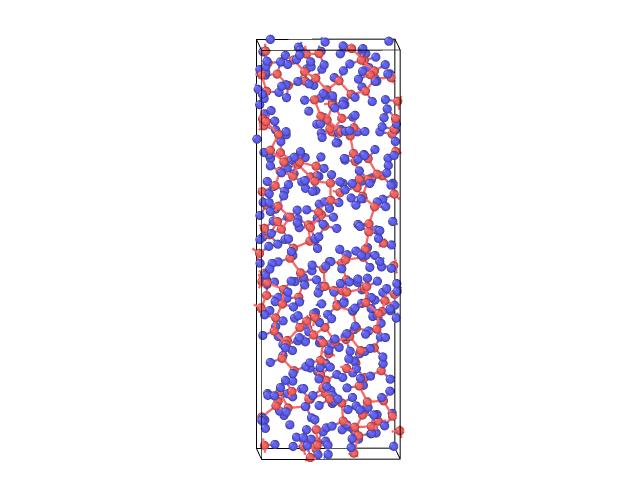

I worked on your point that my parameters were completely wrong. I changed my system to EPON and DETA with ffield.reax.lg which is validated for my system. Now my initial doubt on the failure of CNT before polymer persists. I ran the simulation with NPT ensemble coupling x and y direction and applying ‘fix deform’ in the z-direction. Still, I could see that CNT bonds break before polymer. I ran just EPON and DETA without CNT and observed that polymer bonds never broke, instead I could see that polymer chains being separated (but this happened at a high value of strain).

My doubts are as follows:

- While reaxff can model bond breakage (it shows CNT bond breakage), why polymers don’t show bond breakage. Even at high strains, only the separation of polymer chains is observed.

- Separation of polymer chains can be considered as the creation of voids and thus some sort of failure, how can I quantify this using LAMMPS.

( I tried the same tension test with NVT and ‘fix deform’, in that case, polymer separation happened before CNT failure. But I believe this is not the right method of applying a strain to materials)

ffield.reax.lg (11.6 KB)

in.epon_deta_small (1.72 KB)

param.qeq (217 Bytes)

epon_deta_small.data (302 KB)

control_file (692 Bytes)

this is going beyond formal issues and is not about LAMMPS itself about designing simulations and interpreting simulation results in general. thus it is becoming off-topic for this mailing list.

furthermore, this is neither an area of research that I have a large amount of experience in nor do I have time or interest to fill in for other people’s advisers.

axel.

after having a quick look at your structure I fail to see why you would expect that the polymer bonds should break before (i.e. at a smaller amount of deformation) those of the CNT for the given setup.

can you elaborate why you think so? I would expect the exact opposite.

The strength of CNT to axial tension is more than that of polymers. So when they are reinforced in polymers, higher strength for polymers is expected(the main reason for polymer nanocomposites).

Suppose we have material A with a maximum load capacity of 1 N and material B with 10 N, if we gradually apply tension to material A and B, when the load reaches 1 N A fails and B only fails if it reaches 10 N. Here A is polymer and B is CNT.

And regarding deformation, here, box size is being increased by more than 30 percentage. It is a good amount of deformation, I suppose.

Please correct me if I am wrong in my reasonings and explanations.

yes, I think your logic is flawed.

yes, the CNT is much “stronger”, i.e. you need much more force to stretch it. but that is not what you are comparing.

you are comparing how far you can stretch it before it breaks. and that is a cat of a different color.

your polymer is like a rubber band that you can stretch over a much longer distance. unlike the CNT it can deform significantly (elastic and then plastic) before its bonds will eventually break. the fact that you need much less force to do it does not feature in your simulation setup. by enforcing the distance between the ends of the system or by deforming the box you apply infinite force.

Thanks Axel for your explanation. Yes I could understand that I am not simulating the condition what I actually wanted.

Regards

Abhiram

Let me point out (again) that this kind of discussion is something that you should have with your adviser/supervisor and (experienced) colleagues first.

there is more to a meaningful simulation than using the correct syntax of commands and suitable force field parameters. not all (logic) flaws are as easily exposed as this one.

axel.

Yes, sorry about that. Thanks for your help