Hello,

I am using the solid liquid interface method to calculate the melting point of LiAlO2 (melting temperature is roughly 2000K). I am taking a long cuboidal simulation cell of LiAlO2 and melting a small slab section in the middle of the long box to 6000 K while the rest of the box is at 1800 K. My hypothesis is that the solid liquid interface (SLI) SLI1 and SLI2 should move closer to each other with time as the rest of the box is at 1800 K which is below the melting point of LiAlO2 (MP is 2000K). size of box: 31 X 31 X 113 angstrom

Potential used: core shell potential from "

“Atomistic simulations of the defect chemistry and self-diffusion of Li-ion in LiAlO2.” Energies 12, no. 15 (2019): 2895.

density and structure are correctly reproduced from these potentials.

The inputs and output are given below

Z direction --------->

SLI1 | SLI2 | |

solid | liquid | solid |

1800 K | 6000K | 1800K || |____________ |

The code is given below:

units metal

dimension 3

boundary p p p

atom_style full

fix csinfo all property/atom i_CSID

read_data largecell22.lmp fix csinfo NULL CS-Info

group cores type 1 2 3

group shells type 4

variable z14 equal 0.40zhi+0.60zlo

variable z34 equal 0.60zhi+0.25zlo

region midregion block INF INF INF INF {z14} {z34}

group midgroup region midregion

fix zeromomentum all momentum 1 linear 1 1 1

variable myT equal 1800

velocity all create ${myT} 87287

velocity all zero linear

pair_style buck/coul/long/cs 10 12

pair_coeff * * 0.0 1.000 0.00

pair_coeff 1 4 632.1018 0.2906 0.00 #Li core O shell

pair_coeff 2 4 1109.92381 0.31540 0.00 #Al core O shell

pair_coeff 4 4 12420.5 0.2215 29.07 #O shell O shell

bond_style harmonic

bond_coeff 1 31.0 0.0

kspace_style ewald 2.0e-3

neighbor 1.0 bin

neigh_modify every 20 delay 0 check no

variable time equal step*dt

thermo 100

thermo_style custom step v_time temp pe ke etotal vol press

thermo_modify norm no

initially heat up to ${myT} K, will be reached after about 10 ps with nosehoover npt

to get the correct volume

fix 1 all npt temp {myT} {myT} 0.1 aniso 0.0 0.0 0.1

dump dump1 all custom 1000 dump.therm.gz id type x y z

#dump_modify dump1 sort id

timestep 1.0e-3

run 10000

#write_restart restart.therm

#undump dump1

unfix 1

over melt the mid with berendsen 50 ps

dump dump1 all custom 1000 dump.overmeltmid.gz id type x y z

#dump_modify dump1 sort id

reset_timestep 0

fix 1 midgroup nve

fix 2 midgroup temp/berendsen 6000.0 6000.0 0.1

run 50000

#write_restart restart.overmeltmid

#undump dump1

unfix 1

unfix 2

compute K all ke/atom

variable keeV atom “c_K * 0.043364102”

velocity midgroup create {myT} 87287

velocity all zero linear

dump dump1 all custom 1 dump.melt.gz id type x y z vx vy vz fx fy fz v_keeV

dump_modify dump1 sort id

reset_timestep 0

fix 1 all nve

fix 2 all temp/berendsen {myT} ${myT} 0.1

run 250000

#write_restart restart.melt

undump dump1

unfix 1

unfix 2

Output:

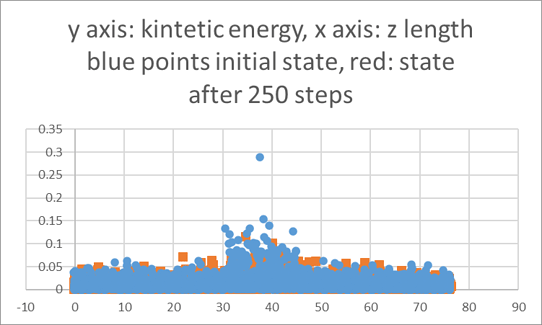

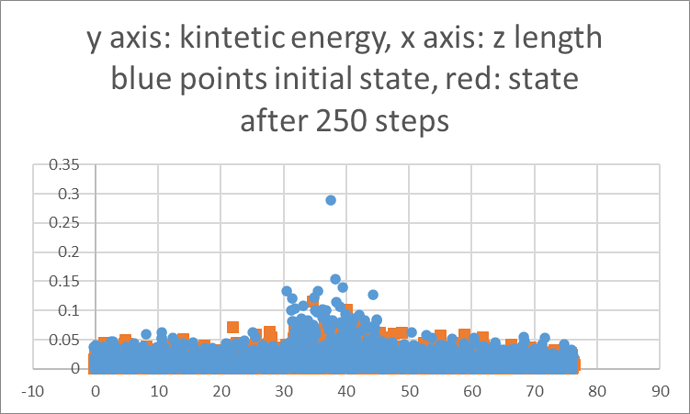

I am plotting the kinetic energy (representative of temperature) vs z coordinates at 2 time instances, First at the beginning of the simulation and second after 250 steps. My time step is 0.001 ps. I expect to see the peak of the kinetic energy to become narrower signifying that the SLIs are moving closer to each other. But instead I am seeing that peaks flattens and broadens.

Question 1: Is my approach correct? Is there a better way to quantitatively track the movement of solid liquid interface?

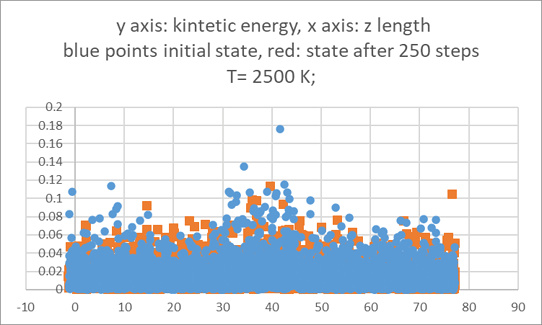

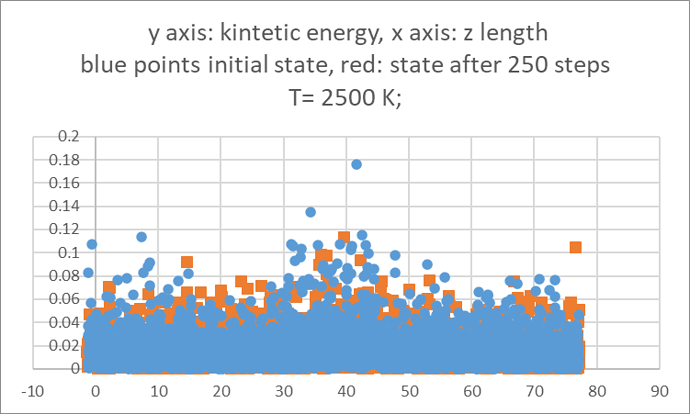

Question 2: If I raise the temperatures of the side sections to 2500K can I expect the SLIs to move away from each other?

The observation for T= 2500K is shown below.

I am not able to see the SLIs move away because the red peak is not becoming wider. Is my hypothesis wrong?

Why are there high energy points at the boundaries in both initial and final states?

Sincerely,

Ankit