The paper investigates how argon flows and boils over a heated substrate (Copper) in a simulation setup with three fluid regions and a copper wall/substrate. A force drives the flow, a Langevin thermostat resets the inlet temperature (at 86K), and data is collected to study boiling.

However, maintaining a constant inlet temperature (86K) causes the liquid temperature to drop unexpectedly (contradicting the results of the paper), preventing boiling, and my guess is that the setup of the reset region (static vs. dynamic) may be contributing to this issue. I’m curious to understand the phenomenon.

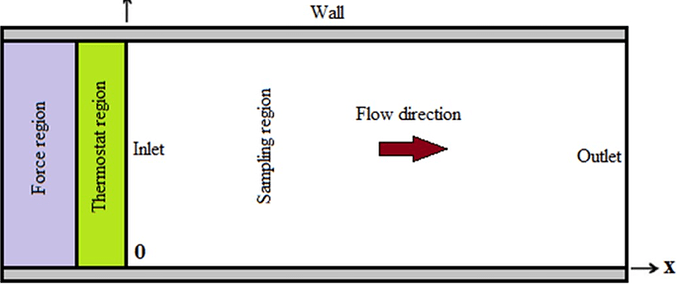

Fluid Regions:

Force Region (0–10mm): A force is applied to drive the argon flow.

Reset Region (10–17mm): The fluid’s temperature is set to 86K to ensure a constant inlet temperature for the next region. The paper uses a Langevin thermostat, but applying it in a continuous flow (where atoms enter and exit) is challenging : atoms are continuously entering & exiting the region.

Study Region (17–370mm): Data is to be collected here to observe boiling and bubble formation.

Copper Wall (3 Layers):

Fixed Layer: Bottom most layer, no heating, just structural support.

Ghost Layer (or popularly known as Phantom layer): Middle layer, heated to 180K to trigger boiling.

Real Layer: Top layer in contact with the fluid, conducts heat from the ghost layer to the argon.

Simulation Method as per the paper:

The system uses a continuous flow with periodic boundaries.

Steps:

NVT run (4ns): Equilibrates the system at 86K.

NVE run (0.2ns): Heats the copper wall’s ghost layer to 180K.

NVE run (4ns): Collects data on temperature and boiling.

The paper doesn’t specify when to apply the force & langevin to reset inlet temperature. Other studies suggest applying the force and Langevin thermostat (for reset region) during the second run, while heating the ghost (phantom) layer.

Issues Summarized:

-

Without the reset thermostat for inlet, flow boiling happens, but liquid argon gets hotter than the wall (180K), which shouldn’t happen (perhaps due to addition of force)

-

With the reset thermostat, the liquid cools down to ~115-120K and stops boiling. Also reset region temperature isn’t maintained at 86K.

Questions:

-

Temperature Drop Problem:

Without the Langevin thermostat (or even with weak damping factor like 10/15/20) in the reset region, argon boils with flow, but the liquid temperature (all liquid) exceeds the wall’s 180K, possibly due to the force in a non-equilibrium state.

With the Langevin thermostat (resetting to 86K), the liquid temperature rises to 115–120K, then drops, and no boiling occurs. Even the thermostate fails to maintain constant 86k at inlet/reset region. Why does this happen? -

Static vs. Dynamic Reset Region:

The ‘reset’ group is defined normally (static) by region, but the flow is dynamic (atoms enter & exit continuously). Could this cause issues? -

If a dynamic ‘reset’ group is used, how can the Langevin thermostat and temperature Computes be applied, since the documentation says LAMMPS doesn’t allow fixes/computes on dynamic groups?

-

If the reset group is static, will the Langevin thermostat affect atoms as they enter the region? (the documentation perhaps says it doesn’t. But will it continue affectig atoms that already left the region?)

Key Part of my input script (I’ve attached both the paper and input script. The picture is symbolic):

input.lmp (3.8 KB)

Main Paper.pdf (6.0 MB)

# Initial Velocities

velocity integration create 86 12345

fix freeze fixed setforce 0.0 0.0 0.0

# Equilibrate the whole system

fix equilibrate integration nvt temp 86 86 0.1

fix spring fgm_integration spring/self 2.93

run 400000 #timestep I set was 5fs. Although the paper works with 2fs.

# I observed the system temperature almost reached at 86k within 2ns

unfix equilibrate

# Heating

variable Th equal 180

fix NVE integration nve

fix temp_elevate ghost langevin 86 ${Th} 0.1 498094 # temp raise of copper substrate

fix cold_inlet reset langevin 86 86 0.5 122345 # cold inlet maintaining

fix force_flow force addforce 0.000185 0.0 0.0 # 300fN

run 40000

unfix temp_elevate

unfix cold_inlet

unfix force_flow

# Data Collection

fix temp_maintain ghost langevin ${Th} ${Th} 0.1 14756

fix cold_inlet2 reset langevin 86 86 5.0 122345 # cold inlet maintaining

fix force_flow2 force addforce 0.000185 0.0 0.0 # 300fN

dump dump2 all atom 10000 dump_final_exp3_3.equil

run 800000