Hi friends

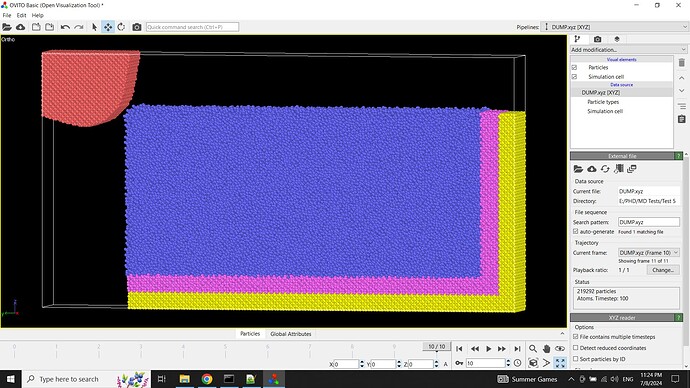

I ran into a problem for machining simulation. As seen in the figure, when the tool reaches the workpiece, the workpiece enlarges and exits the crystalline state. Can you help me to fix the problem?

How fast are you moving the tool? Check out what this means in meters per second.

variable v index -0.5 #Machining Velocity (in Angstrom/ps = *100m/s)

variable depth equal 10.5 #Depth of Cut (in Angstrom)

variable radius equal 30 # Tool Edge Radius

variable z0 equal “30 * v_latparam” # Z coordinate of tool circle center. This is the initial distance between tool circle center and WP surface.

variable zmove equal " -v_z0 + v_radius - v_depth " #Z-movement of the tool to reach to the desired depth of cut

displace_atoms tool move 0 {initialdist} {zmove} units box

with this command the velocity is infinite, since the displacement is instantaneous.

Thank you for your guide.

How can I change and modify?

I don’t understand this question.

i changed this line of cod;

displace_atoms tool move 0 0 ${zmove} units box

But the problem was not solved.

how can i solve that/

Thank you

I have many cases including

Potential

ensembel

Fixes

I checked but the problem is not solved. Is it possible to advise?

It is possible to give advice, but for that you first have to provide more detailed information and explain the problem and the steps you did (and why) to resolve the problem.

That you provided a picture is helping a lot, the remainder of the information is very vague and poor, though. Please have a thorough look at the forum guidelines and follow the suggestions given there. Please also try to find somebody that can help you with writing in english and that can correct your grammar and spelling. That will make it much easier to understand what you are asking.

Please also note, that similar simulations have been discussed in the past, so there should be useful information in the archives. Similarly, helpful information should be in publications about the process. Some are even listed with pictures in the corresponding section of the LAMMPS home page.