Dear All,

I want to perform nanoindentation test on a 2D monolayer material ( the structure is like graphene in the XY plane) along the thickness direction (Z direction) in Lammps. Initially, I could do the indentation test by using the “Fix Indent” command with spherical indenter and fixing a sublayer at the bottom by “Fix Setforce=0.0” command.

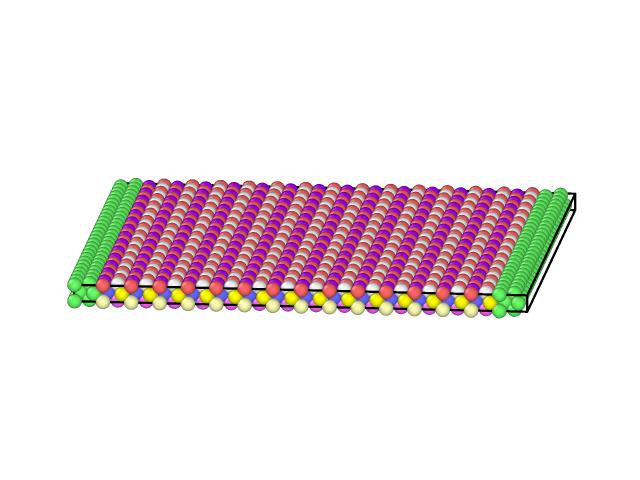

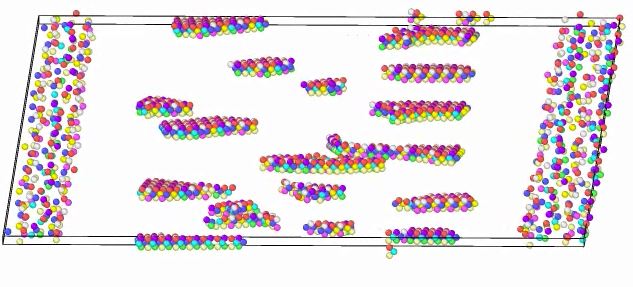

However, now I want to do a similar indentation test using somewhat different boundary conditions. Rather than fixing the bottom of the substrate, I want to clamp the film on both sides and then indent through the thickness direction. (please see the attached snapshot for a visualization of the boundary condition. Green atoms represent the clamped portion on both sides of the substrate). With that boundary condition in mind, I tried to apply “Fix set force =0.0” command on both sides of the film and “Fix indent” through the thickness. But, it seems that the structure just breaks away at the two clamped regions rather than indenting through the thickness. So, my question is that is it possible to use “Fix indent” without fixing atoms at the bottom in the indentation direction? It would be really helpful if anyone could provide any insight. I also copied here the main parts of the input script I used for reference.

Thank you so much.

Regards

Shoieb Ahmed Chowdhury

Graduate Student

Dept. of Mechanical Engineering

University of Rochester

Rochester, NY 14627

Input script:

#1 general

units metal

dimension 3

atom_style atomic

neighbor 0.3 bin

#2 structure

boundary p p s

read_data lammps.dat

#3 variables

variable temperature equal 1.0

variable pressure equal 0.1

variable tstep equal 0.001

#indenter radius

variable radius equal 20.0

#regions on side of the structure where it will be clamped

region clamped1 block 0 5 INF INF INF INF units box

region clamped2 block 92 INF INF INF INF INF units box

#define group of atoms on side of the substrate where it will be #clamped

group clamped1 region clamped1

group clamped2 region clamped2

group clamped union clamped1 clamped2 #side clamp boundary

#for visualization in Ovito whether the correct boundary is set

#set group clamped type 9

#4 potentials

#output the initial structure

write_data data_initial

#5 optimize at 0 K

dump 1 all custom 50000 dump.minimization id type x y z

min_style cg

minimize 0.0 1.0e-8 10000 1000000

undump 1

#unfix 1

#6 optimize at T

compute peratom all pe/atom

reset_timestep 0

timestep ${tstep}

#assign initial velocities

compute new all temp #id new computes temp of mobile group (indenter)

velocity all create 1.0 482748 temp new mom yes rot no

fix 1 all npt temp {temperature} {temperature} 1 x {pressure} {pressure} 1 y {pressure} {pressure} 1 drag 1.0

dump 1 all custom 1000 dump.optimize.*cfg id type x y z c_peratom fx fy fz

thermo 1000

thermo_style custom step lx ly lz press pxx pyy pzz pe temp

neigh_modify once yes

run 20000

reset_timestep 0

#output the optimized structure

write_data data_equilib

run with indenter

variable k equal 1.0

variable zdn equal “74.0 -(stepdt0.1)”

compute 1 all pressure thermo_temp

#zero out all the forces on the side boundary

fix 2 clamped setforce 0.0 0.0 0.0

fix 4 all indent k sphere 50 20 v_zdn {radius} units box#command for #creating an indenter with force k.

undump 1

dump 1 all custom 1000 dump.indentation*cfg id type x y z fx fy fz

#8 run MD

thermo 1000

#thermo 1000

thermo_modify temp new

thermo_style custom step temp f_4[3] elapsed lx ly lz zlo zhi

run 100000