Hello,

I am trying to simulate a Copper-Coated SWCNTs in Al Metal Matrix Composites to find its mechanical characteristics. Before Minimization and Thermal Equilibration, I have frozen cnt and coating. When I am running my code, the matrix is getting distorted.

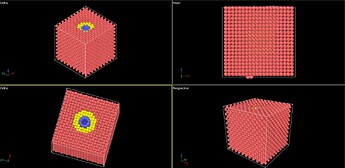

Before:

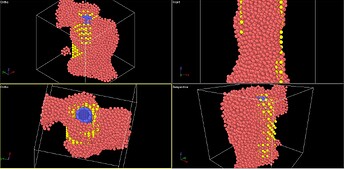

After:

Is there any problem with defining Interatomic Potential ?

What should I do now?

Code:

units metal

variable T equal 300

variable dt equal 0.01

dimension 3

boundary p p p

atom_style atomic

read_data model.lmp

#### Assign atom types

mass 1 26.98 # Al

mass 2 12.01 # C

mass 3 63.546 # Cu

#### Define interatomic potentials using hybrid

pair_style hybrid airebo 10.2 eam/alloy lj/cut 4.5

pair_coeff * * airebo CH.airebo NULL C NULL

pair_coeff 1 2 lj/cut 0.03438 3.01

pair_coeff 3 2 lj/cut 0.02578 3.0825

pair_coeff * * eam/alloy al-cu-set.eam.alloy Al NULL Cu

#### Define groups

group CNT type 2

group coating type 3

group CNT_coating union CNT coating

group matrix subtract all CNT_coating

#### Freeze CNT and coating atoms during minimization

fix freezeCNT_coating CNT_coating setforce 0.0 0.0 0.0

#### Define simulation parameters

neighbor 2 bin

neigh_modify delay 0 every 1 check yes

#### energy minimization

min_style cg

minimize 1.0e-6 1 10000 10000 # Energy tolerance = 1.0e-6, Force tolerance = 1.0eV/Å

#### Thermal Equilibration under NPT (40 ps)

velocity matrix create 300.0 5812775 mom yes rot yes dist gaussian # Initialize at 300 K

fix 1 matrix npt temp 300.0 300.0 $(100.0*dt) iso 0.0 0.0 $(1000.0*dt) # NPT ensemble, 0 bar pressure

fix 5 matrix temp/rescale 10 300 300 1 0.5

timestep 0.0001 # Time step of 1 fs

thermo 100

dump 1 all custom 100 dump_n1.lammpstrj id type x y z

run 10000

unfix freezeCNT_coating

unfix 1

#### Uniaxial Tensile Deformation in z-direction (NVT Ensemble)

timestep 0.01

fix 2 matrix nvt temp 300.0 300.0 $(100.0*dt) # NVT ensemble at 300 K

fix 3 all deform 1 z erate 1.0e-4 remap x

#### Output strain and stress info to file

#### For units metal, pressure is in [bars] = 100 [kPa] = 1/10000 [GPa]

#### p2, p3, p4 are in GPa

variable tmp equal "lx"

variable L0 equal {tmp}

print "Initial Length, L0: ${L0}"

variable strain equal "(lz - v_L0)/v_L0"

variable p1 equal "v_strain"

variable p2 equal "-pxx/10000"

variable p3 equal "-pyy/10000"

variable p4 equal "-pzz/10000"

fix def1 all print 100 "{p1} {p2} {p3} {p4}" file alloy.def1.txt screen no

dump 2 all atom 50 dump.final

thermo 100

thermo_style custom step v_strain temp v_p2 v_p3 v_p4 ke pe press

run 200000 ```