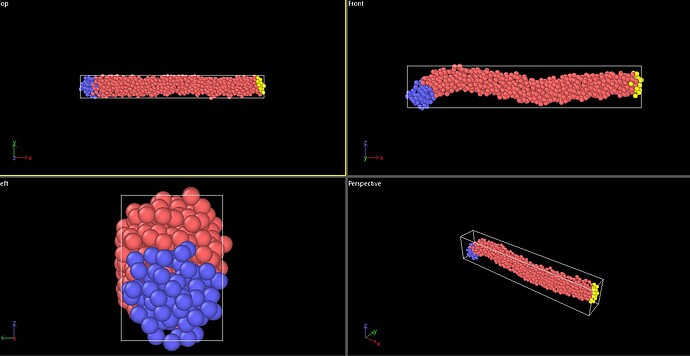

Hi all — I need help diagnosing a problem with a LAMMPS simulation of an amorphous silicon (a-Si) nanobeam under bending.

What I’m doing:

I used an LAMMPS workflow that worked fine for crystalline, isotropic Si. To get an amorphous beam I:

- Created a small periodic amorphous Si block (a-Si seed) by melting a diamond lattice and quenching, then wrote the result to aSi_tile.data:

# Create a small periodic amorphous silicon block (a-Si seed)

# Units: metal | Potential: Stillinger–Weber | Lattice: diamond

variable S equal 4

units metal

dimension 3

atom_style atomic

boundary p p p

# 1. Create crystalline Si seed

lattice diamond 5.43

region box block 0 ${S} 0 ${S} 0 ${S} units lattice

create_box 1 box

create_atoms 1 region box

mass 1 28.0855

# 2. Define potential

pair_style sw

pair_coeff * * Si.sw Si

neighbor 2.0 bin

neigh_modify delay 10 check yes

# 3. Initialize

timestep 0.001 # 1 fs

velocity all create 300.0 12345 mom yes rot yes dist gaussian

thermo 1000

thermo_style custom step temp press pe etotal vol

# 4. Melt crystalline Si

fix melt all npt temp 300.0 3500.0 0.1 iso 0.0 0.0 1.0

dump 001 all custom 1000 melt.xyz id type x y z

run 50000 # 50 ps

unfix melt

undump 001

# 5. Quench to amorphous

fix quench all npt temp 3500.0 300.0 0.1 iso 0.0 0.0 1.0

dump 002 all custom 1000 Quench.xyz id type x y z

run 100000 # 100 ps

unfix quench

undump 002

# 6. Relax at room temperature

fix relax all npt temp 300.0 300.0 0.1 iso 0.0 0.0 1.0

dump 003 all custom 1000 relax.xyz id type x y z

run 20000 # 20 ps

unfix relax

undump 003

# 7. Output periodic amorphous block

write_data aSi_tile.data # will be used for replication

dump 1 all custom 200 dump_aSi_tile.lammpstrj id type x y z

- Read aSi_tile.data into a second script, replicated it along x to make the beam, set fixed and mobile end regions, equilibrated, then bent the beam by moving the mobile end with fix move:

# LAMMPS script for bending of a silicon nanobeam using fix move

variable S equal 4 # Length scale

variable velmob0 equal 0.001

variable velmob equal (-1)*${velmob0}*${S}

variable iterequi equal 100000

variable iterrun equal 5300000

variable T equal 300

variable dt equal 0.001

timestep ${dt}

variable latconst equal 5.431

# Define nanobeam dimensions

variable XNW equal 10*${S}*${latconst}

variable YNW equal 1*${S}*${latconst}

variable ZNW equal 1*${S}*${latconst}

variable L_fixed equal 0.1*${XNW}

variable L_mobile equal 0.15*${XNW}

variable XEdge equal ${XNW}+v_L_fixed+v_L_mobile

units metal

atom_style atomic

dimension 3

boundary s s s

# Read a-Si tile and replicate

read_data aSi_tile.data

replicate 12 1 1 # 12× along x-axis (beam length)

# Define regions and groups

region fixed block 0 ${L_fixed} 0 ${YNW} 0 ${ZNW} units box

group fixed region fixed

variable limX1 equal ${XEdge}-v_L_mobile

region mobile block ${limX1} ${XEdge} 0 ${YNW} 0 ${ZNW} units box

group mobile region mobile

group middle subtract all fixed mobile

set region fixed type 2

set region mobile type 3

dump 009 all custom 1 initial.xyz id type x y z

run 1

undump 009

# Potential

pair_style sw

pair_coeff * * Si.sw Si Si Si

# Minimize and equilibrate

min_style cg

minimize 1.0e-6 1.0e-6 1000 10000

velocity all create ${T} 48284121 mom yes rot yes

fix 1 all nvt temp ${T} ${T} $(100.0*dt)

# Computes...

compute FXeqATOM all property/atom fx

compute FXeq all reduce sum c_FXeqATOM

compute FYeqATOM all property/atom fy

compute FYeq all reduce sum c_FYeqATOM

compute FZeqATOM all property/atom fz

compute FZeq all reduce sum c_FZeqATOM

dump 000 all custom 20000 dumpequilibration.xyz id type x y z

thermo 1000

thermo_style custom step temp pe ke etotal c_FXeq c_FYeq c_FZeq

run ${iterequi}

unfix 1

undump 000

# Production: apply bending

reset_timestep 0

fix 5 middle nvt temp ${T} ${T} $(100.0*dt)

fix 2 fixed move linear 0 0 0 units box

fix 4 mobile move linear 0 ${velmob} 0 units box

variable disp equal (-1)*step*${dt}*${velmob}

compute peatom middle pe/atom

compute potential middle reduce sum c_peatom

compute keatom middle ke/atom

compute kinetic middle reduce sum c_keatom

compute FYAtom1 fixed property/atom fy

compute FYfixed fixed reduce sum c_FYAtom1

compute FYAtom2 mobile property/atom fy

compute FYMobile mobile reduce sum c_FYAtom2

compute mystress all stress/atom NULL virial

compute myTemp middle temp

fix result all ave/time 1 10000 10000 c_myTemp c_potential c_kinetic v_disp c_FYfixed c_FYMobile

thermo 10000

thermo_style custom step f_result[1] f_result[2] f_result[3] f_result[4] f_result[5] f_result[6]

dump 2 all custom 500000 dumpFast.lammpstrj id type xs ys zs c_mystress[1] c_mystress[2] c_mystress[3]

log logFigure.txt

run ${iterrun}

Problem:

Right after the equilibration step (the initial long run), the straight nanobeam spontaneously deforms into a weird shape before I start the bending run. This deformation happens immediately after equilibration and corrupts my bending results.

I would appreciate any hints or help identifying the likely causes. Thanks!