Lammps Users,

David

-Is this an unbiased temperature calculation, or the temperature from a compute temp/deform?

the only compute command used was for pressure 'compute 1 all pressure thermo_temp' and using the 'thermo_style cutsom temp' command to get the temperature. So it should just be the Nose-Hoover style. Does that mean unbiased? And do you think adding the compute could affect the temperature?

Axel

- do you have a well equilibrated starting configuration?

>it was run for over 10 ns in npt before switching

- does your system conserve energy when you run without shearing (using fix nve)? does it properly maintain equilibrium (using fix nvt)?

ran for 2ns in nvt (it fluctuates a lot but still averages to 298K)

- is your time step adequate? when shearing, you probably should reduce the time step from what is suitable for a regular bulk system.

the time step was 0.01 in "real" units

- is your system large enough?

it has 343 molecules (7x7x7 box)

- does it maintain a suitable velocity profile with a very small straining rate?

from what I could tell, the velocity profile looked stable and the gradient didn't fluctuate much.

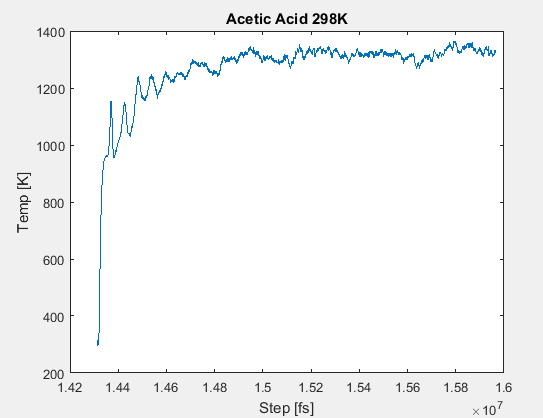

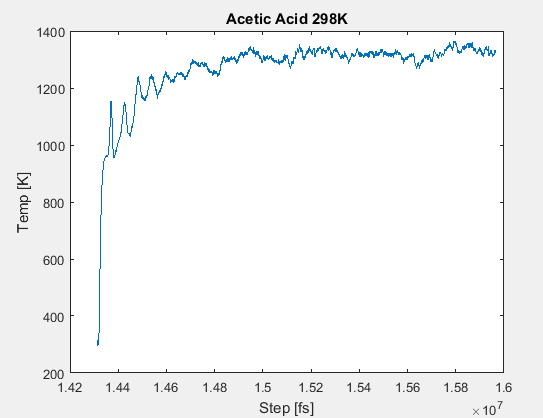

I did a log-scale strain sweep from 0.0000001- 100.0. It started having trouble regulating temp at 0.0001 strain rate and skyrocketed above that. The .00001 and 0.0001 were the only 2 points that were reasonable, viscosity value was .8 cP while experimental of 1.1cP.

I can get more points in this range, but was wondering if there was a better way to either: regulate the temperature to achieve higher strain rates and/or control the pressure more precisely for the lower strain rates, to get more data points?

Thanks for the Reply,

Undergrad Research

Tyler