Hi everyone,

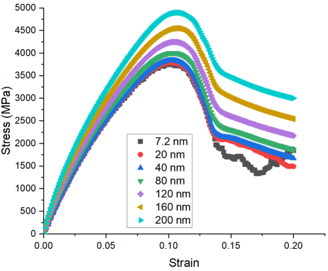

I want to determine the size of the bulk cell to be used. I check different bulk cell size.

When doing the compression of copper single crystals, except for the size of the bulk cell I used, the other conditions used are the same (periodic boundary conditions are applied). Why do the resulting Young’s modulus and yield strength increase as the bulk cell size increases? Why am I not seeing convergence? Can anyone give me some advice about this? Thank you in advance!

The following are the script I used:

------------------------ INITIALIZATION ----------------------------

units metal

dimension 3

boundary p p p

atom_style atomic

variable latparam equal 3.597

----------------------- ATOM DEFINITION ----------------------------

lattice fcc {latparam}

region whole block 0 55 0 55 0 55

create_box 1 whole

region upper block INF INF INF INF INF INF units box

lattice fcc {latparam} orient x 1 0 0 orient y 0 1 0 orient z 0 0 1

create_atoms 1 region upper

------------------------ FORCE FIELDS ------------------------------

pair_style eam/alloy

pair_coeff * * Cu01.eam.alloy Cu

------------------------- SETTINGS ---------------------------------

compute csym all centro/atom fcc

compute peratom all pe/atom

######################################

EQUILIBRATION

reset_timestep 0

timestep 0.001

velocity all create 300 12345 mom yes rot no

fix 1 all npt temp 300 300 1 iso 0 0 1 drag 1

Set thermo output

thermo 1000

thermo_style custom step pxx pyy pzz pe temp lx ly lz press

run 300000

unfix 1

Store final cell length for strain calculations

variable tmp equal “lx”

variable L0 equal {tmp}

print "Initial Length, L0: {L0}"

######################################

DEFORMATION

reset_timestep 0

fix 1 all npt temp 300 300 1 y 0 0 1 z 0 0 1 drag 1

variable srate equal 1.0e10

variable srate1 equal “-v_srate / 1.0e12”

fix 2 all deform 1 x erate ${srate1} units box remap x

variable strain equal “(lx - v_L0)/v_L0”

variable p1 equal “v_strain”

variable p2 equal “-pxx/10000”

variable p3 equal “-pyy/10000”

variable p4 equal “-pzz/10000”

fix def1 all print 100 “{p1} {p2} {p3} {p4}” file Cu_comp_100.def1.txt screen no

Use cfg for AtomEye

dump 1 all cfg 100 dump.comp_*.cfg mass type xs ys zs c_csym c_peratom fx fy fz

dump_modify 1 element Cu

thermo 1000

thermo_style custom step v_strain temp v_p2 v_p3 v_p4 ke pe press

run 20000