Dear LAMMPS Users,

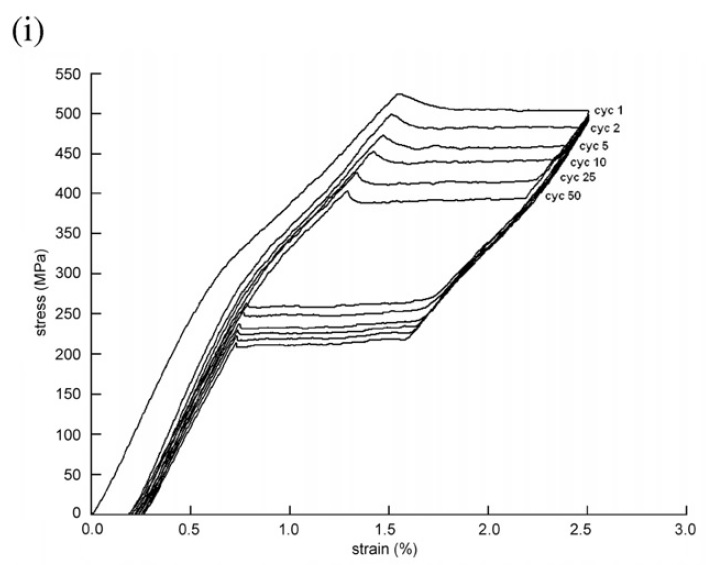

I am trying to simulate a simple tensile test in LAMMPS. All I am trying to do is to stress the specimen upto yield point and then release this stress. During the experiments, I can do this simply by removing the load and I can get an attached plot something like the file name (desired).

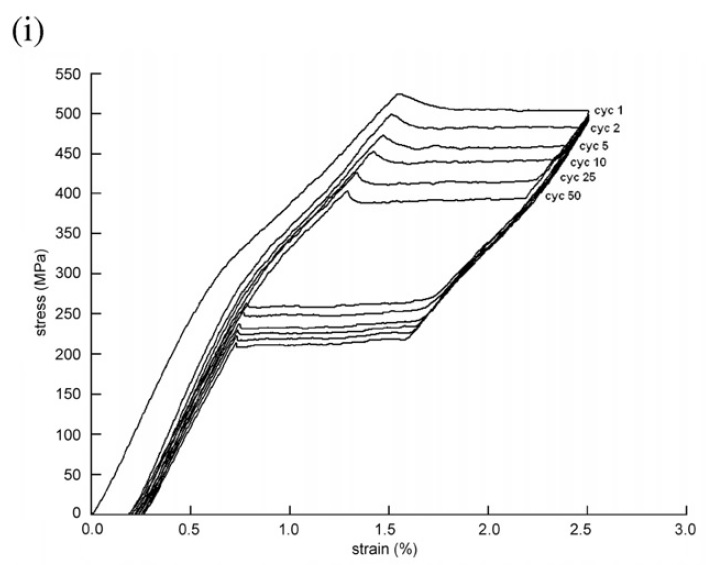

The first question is how can I remove this stress during simulation. To do this I applied negative strain as follows and got the attached plot of stress-strain.

fix 2 all deform 1 y erate ${srate1} units box remap x

run 1000

unfix 2

fix 2 all deform 1 y erate -${srate1} units box remap x

run 1000

My second question is that by applying the negative strain (to replicate experiments) I am ending up having some negative strain hystersis and also the stress-strain curve at the start of simulation begun with a negative stress value. How could I overcome these problems?

SG

Repeated tensile test.xls (37 KB)

WOW … Your attached graph make no sense to me at all (sorry) … Here are a few comments: If you apply a negative strain your are not removing the stress, but compressing the sample … Am … If your simulation is right, then the stress should increase on upon the yield point then the stress should drop dramatically i think removing the load is likely forcing the system to do something its not intent to happen …Hope this helps …

A salute

Oscar G.

Thank you for your reply Guerrero. But your reply has not given me any solution.

My question is still the same, While I use the following command to run displacement controlled tensile test, What can I do to get a stress-strain plot if I want to remove the strain just before the yielding (as in you said, the stress should dramatically drop)

fix 2 all deform 1 y erate ${srate1} units box remap x

run 1000

You seem to be misunderstanding something when translating from the macroscale to nanoscale. While yes, on the macroscale your sample is returning to it’s original relative size, you are not actively compressing it. Rather, you are allowing it to relax back to a state where it is nonstressed by removing the load before stressing it again. What you are doing using molecular dynamics is actively compressing your material (as Oscar mentioned) instead of allowing it to relax.

I will admit that I am not certain how to do this procedure using molecular dynamics (although I am familiar with doing it experimentally), but a brief google search of “molecular dynamics cyclic loading” shows that there are numerous papers claiming to have performed cyclic loading using MD. Therefore I recommend searching the literature to get a better idea of what you need to do…

A comment about your input, if you do continue to perform the deformations as you are trying to do, I recommend reconsidering using fix deform erate. As you have it written currently (assuming I remember correctly), your box will be deformed more quickly when you are compressing your sample because erate determines the rate of deformation based on the box length in that direction when the deformation begins (someone please correct me if I am wrong…).

Michael

ANSWER: Ok …Ammmm … Let me think …First run a tensile test and identify the yield strain . Once you know where the stress drops, then re-run the simulation… For example, Let say your sample yields at 14% , thus you re-run the simulation and strain the sample to 14.5 % , then unfix erate and run NVE …I would never apply a negative strain (Compress) or perturbe the system by other means, because I think your are forcing the system to do something its not mean to happen. When you run NVE your are letting the systems evolve naturally ……

Hope this helps

Oscar G.