Dear lammps users,

It sent this message yesterday but seems that the email was not sent

correctly and the thread is empty. So I am sorry if you are recieving

this for the second time.

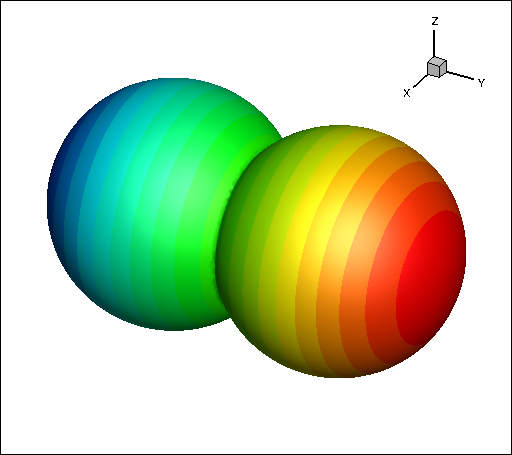

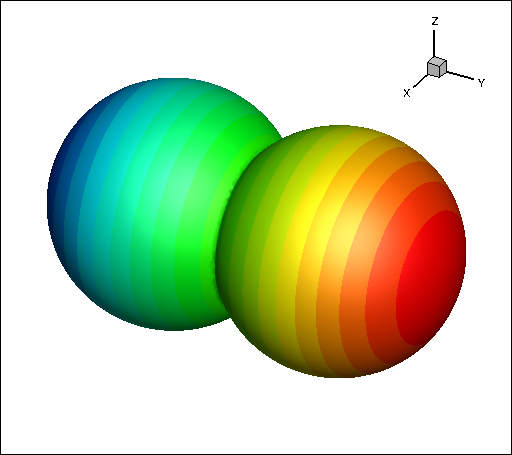

I'm trying to simulate shear flow of non-spherical

particles (dumbblle shape) using fix rigid and granular package

(version: 9-Oct).

The particles are create from two overlapping spheres (see attached

figure) and initially configured in a 25x25x25 lattice (using pizza.py)

with a vol fraction of 0.6

I am using the following script for my simulation

units si

atom_style sphere

boundary p p p

newton off

comm_modify mode single vel yes

#Read the Cluster of compound particles and add mol property

fix addMolecule all property/atom mol ghost yes

read_data dumbells.dat fix addMolecule NULL Molecules

#Relax the particles

pair_style gran/hooke/history 2000 NULL 50 NULL 1 0

pair_coeff * *

velocity all create 1e15 1234 loop geom

neighbor 0.003 bin

neigh_modify delay 0 every 1 check yes

timestep 1e-5

fix 1 all rigid molecule

run 30000

#Remove Previous Settings

unfix 1

uncompute 1

uncompute 2

reset_timestep 0

#New Seetings

change_box all triclinic remap

pair_style gran/hooke/history 2000 NULL 50 NULL 0.5 1

pair_coeff * *

timestep 1e-5

fix 1 all rigid molecule

fix shearRun all deform 1 xy erate ${shearRate} remap v units box

run ${NSTEPS}

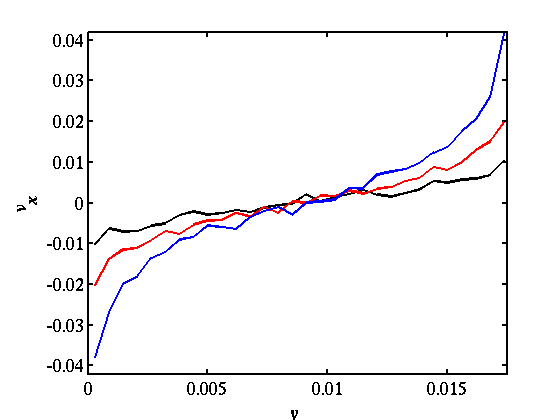

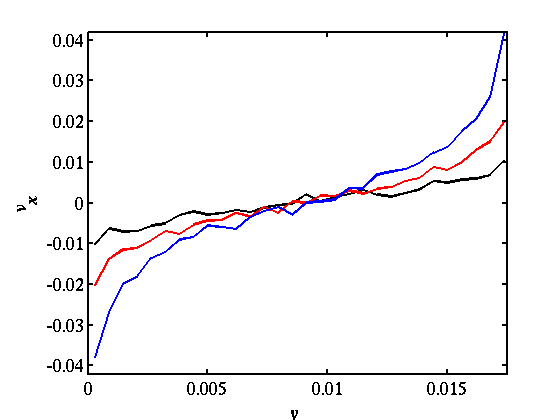

I expect to get a linear velocity profile but I get an S shape profile.

This is independant of the time step size. I have attched velocity

profile results for three different shear rates. At very low rates

(\{shearRate\}\~1\) the profile is almost linear but this quickly changes

to an S shape by slightly increasing the shear rate \({shearRate}>2).

The simulation also seems to have reached steady state since I tested it

with two different ${NSTEPS} with larger nstep twice the smaller one.

I appriciate any ideas or suggestions from the developpers or the community.

Regards - Sina

untitled.png

twoParticle.png

Dear lammps users,

It sent this message yesterday but seems that the email was not sent

correctly and the thread is empty. So I am sorry if you are recieving

this for the second time.

i am now seeing it for the third time.

the thread is empty, because nobody felt compelled to answer. please

note that this forum is a volunteer effort, so there is no guarantee

for an answer, especially on a topic that not many people are familiar

with (like me).

if i had a guess, i would think that your understanding of what is a

large or small shearing rate is different from what fix deform does.

axel.

Dear Axel,

Thank you for your reply. I absolutly understand that this is not a

commercial software and is based on voluntery efforts of people like

yourself and no one is obliged to provide and answer. I also definitly

didn't mean to bombard the mailing list to get an answer and sorry that

you got this three times. I just thought I had sent a blank email.

Anyways, thanks for your suggestion. I will try to redo my simulations

with smaller rates or non-dim my system to get more consistent values.

Thank you again

Sina

Sina,

There are a number of things you can try (and I highly suggest you that you try them!) An S profile (at steady state) is indicative of non-local effects (velocity not purely determined by local “state”- there is some additional length scale), which are doubtful to appear for periodic(triclinic) domains as there is nothing special about the boundaries. Your system is simple enough that I doubt there is anything extraordinarily special happening.

#1 - initialize with a velocity ramp consistent with your deformation. This should help alleviate any problems encountered from momentum transfer across the boundaries at start-up.

#2 - Try smaller volume fractions, dimers will need more space to re-orient themselves. 0.6 is already close to jamming for spherical particles ~0.62, dimers should take less confinement to become frustrated. I wouldn’t be surprised if you get shear banding. Though this should not happen consistently in the same place for your BCs unless its an artifact from start-up.

#3 You can also check for phenomena like this by defining some nice correlations that you want to look at (I can’t give too much away for free).

#4 - do non-dimensionalize your system! Look at granular literature, that will give you a good place to start. I would suggest Campell’s papers from early 2000s.

#5 - If you want some help, its best to attach all the info someone needs to test your case.

Eric,

Thank you for your suggestions, initializing the atoms to an initial

linear profile has no effects on the final S shape profile.

Volume fraction however, seems to be somewhat responsible for this. Also

at vol frac of 0.6 all shear rates generate same S shape profile (the

figure I attached yesterday at vol frac 0.6 and smallest shear rate was

not averaged for long enough total shear)

Sina

I can’t say much without an actual case to run. But if you’re getting the same S-profile in every case, something is wrong with the way you’re simulating things. Averaging over different realizations of your system should produce a homogeneous shear with your boundary conditions, no matter what.

Assuming you are trying to simulate a physical system.

Hi,

Yes I am trying to simulate a physical system. Attached is an actual case; dumbellsV056.dat is the initial configuration with vol fraction of 0.56.

run.in is the input script and I was using 9Oct version for my previous runs.

Thanks

Sina

Quoting Eric Murphy <[email protected]...> on Mon, 22 Dec 2014 16:15:17 -0600:

dumbellsV056.dat (403 KB)

run.in (1.5 KB)